Dec . 07, 2024 03:33 Back to list

4 hdpe drain pipe manufacturer

Understanding 4% HDPE Drain Pipe Manufacturers Key Insights

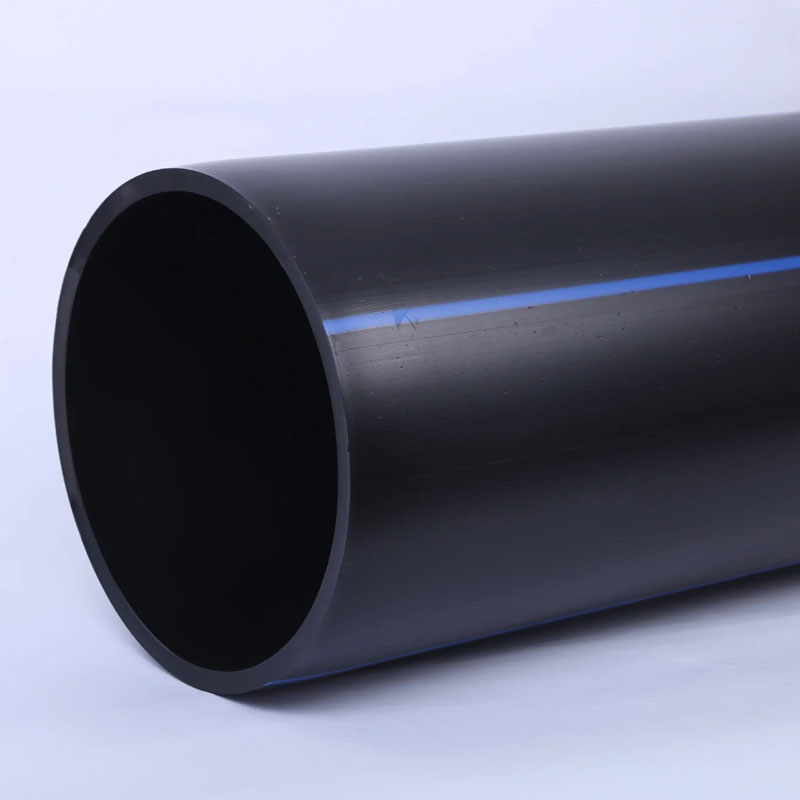

In the construction and civil engineering sectors, high-density polyethylene (HDPE) drain pipes have gained significant popularity due to their robust characteristics and versatility. As the demand for efficient water management systems continues to rise, the role of 4% HDPE drain pipe manufacturers becomes increasingly critical. This article delves into the advantages of HDPE drain pipes, the manufacturing process, and what to look for when choosing a supplier.

What is HDPE?

High-density polyethylene (HDPE) is a thermoplastic polymer made from petroleum. It boasts a high strength-to-density ratio, which gives it superior characteristics compared to other materials. HDPE is known for its resilience, chemical resistance, and durability, making it a preferred choice in various applications, including drainage, plumbing, and waste management.

Advantages of HDPE Drain Pipes

1. Durability and Longevity HDPE drain pipes are resistant to corrosion, chemicals, and environmental factors, ensuring a long lifespan even in challenging conditions. This durability translates to lower maintenance costs over time, making them a cost-effective choice for both residential and commercial projects.

2. Flexibility One of the most significant advantages of HDPE is its flexibility. This characteristic allows for easier installation in various terrains and makes it less susceptible to cracking under pressure. Additionally, the flexibility makes HDPE drain pipes ideal for use in areas with shifting soils.

3. Lightweight Compared to traditional materials like concrete or steel, HDPE is significantly lighter, which simplifies transportation and installation. The reduced weight allows for easier handling and can lead to lower labor costs during installation.

4. Environmental Impact HDPE is 100% recyclable, contributing to sustainable construction practices. Manufacturers are increasingly focusing on environmentally friendly production methods, making HDPE a more appealing choice for eco-conscious projects.

5. Hydraulic Performance HDPE drain pipes have smooth inner walls, minimizing friction and promoting efficient water flow. This characteristic is crucial in drainage systems as it helps prevent blockages and reduces the risk of flooding.

The Manufacturing Process of HDPE Drain Pipes

The manufacturing of HDPE pipes involves several steps, ensuring that the final product meets industry standards and customer requirements

4 hdpe drain pipe manufacturer

1. Raw Material Preparation The process begins with the selection of high-quality polyethylene resin. The material is often compounded with additives to enhance properties like UV resistance and stabilize it against heat.

2. Extrusion The prepared resin is fed into an extruder, where it is heated and melted. The molten polyethylene is then forced through a die, shaping it into a pipe.

3. Cooling Once shaped, the pipes are cooled to solidify. This can be done using various methods, including water baths or air cooling.

4. Quality Control Manufacturers conduct stringent quality checks throughout the production process to ensure that the pipes meet the required specifications concerning diameter, thickness, and strength. This step is crucial to promote safety and reliability.

5. Packaging and Distribution After passing quality checks, the pipes are cut to specific lengths, bundled, and prepared for delivery. Efficient logistics ensure that the pipes reach construction sites promptly.

Choosing the Right 4% HDPE Drain Pipe Manufacturer

When selecting a manufacturer, it is essential to consider several factors to ensure quality and reliability

- Experience and Reputation Look for manufacturers with a proven track record and positive customer feedback. Experienced companies are more likely to comply with industry standards and deliver high-quality products.

- Certifications Manufacturers should have relevant certifications, such as ISO standards, which demonstrate their commitment to quality and safety.

- Customization Options Some projects may require specific sizes or features. Choose a manufacturer that offers customization to meet your project's unique demands.

- After-Sales Support Reliable manufacturers will provide after-sales support, including installation guidance and warranty services, ensuring you're not left alone after the purchase.

In summary, 4% HDPE drain pipe manufacturers play a pivotal role in modern construction and infrastructure projects. By understanding the advantages of HDPE, the manufacturing process, and the key factors to consider when choosing a supplier, you can make informed decisions that lead to successful water management systems. As the industry continues to evolve, opting for high-quality HDPE drain pipes will ensure robust and efficient solutions for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025