Nov . 25, 2024 09:34 Back to list

4 double wall corrugated pipe factories

Understanding 4% Double Wall Corrugated Pipe Factories An Overview

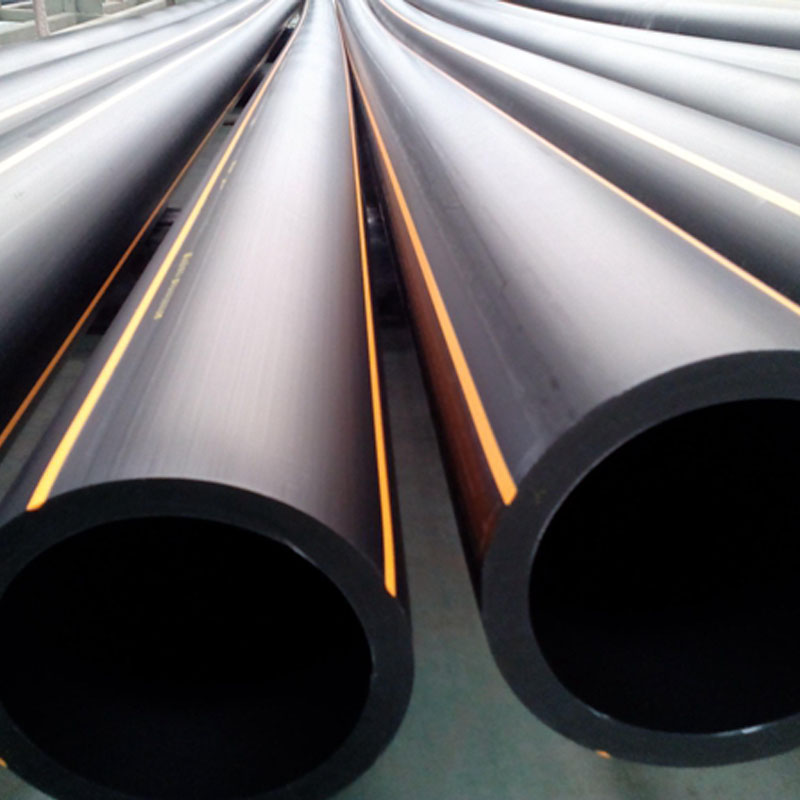

In the realm of modern manufacturing, the production of high-quality piping systems is paramount for both construction and infrastructure projects. Among the various piping solutions available, 4% double wall corrugated pipes have emerged as a preferred choice due to their unique structural integrity, durability, and versatility. This article delves into the factories that specialize in the manufacturing of these advanced piping systems, shedding light on their processes, materials, and benefits.

What is Double Wall Corrugated Pipe?

Double wall corrugated pipe consists of two distinct layers – an internal smooth layer that facilitates fluid movement and an external corrugated layer that provides reinforcement. The corrugation enhances the pipe’s strength without adding significant weight, making it easier to handle during installation. The 4% double wall refers to the thickness of the pipe material, ensuring that it can withstand various physical stresses and environmental conditions while maintaining a lightweight profile.

Manufacturing Process

The production of 4% double wall corrugated pipes involves several key stages

1. Material Selection The primary materials used for manufacturing these pipes are high-density polyethylene (HDPE) or polypropylene. These materials are chosen for their excellent resistance to chemicals, UV rays, and physical impact, resulting in a long lifespan.

2. Extrusion The selected plastic pellets are fed into an extruder, where they are heated until they melt. The molten material is then forced through a die that shapes it into the desired pipe profile.

3. Forming the Double Wall Once the base layer is formed, a second layer is extruded onto the first layer through a co-extrusion process. This technique allows for the simultaneous production of the smooth inner surface and the corrugated outer layer, which enhances the pipe’s structural strength.

4. Cooling and Sizing After extrusion, the pipe must be cooled to solidify its structure. This is typically done using a water bath or air-cooling method. Once cooled, the pipe is sized to meet specific diameter requirements.

4 double wall corrugated pipe factories

5. Cutting and Quality Control The finished pipes are cut to predetermined lengths and undergo rigorous quality control inspections. These tests ensure that the pipes meet industry standards for durability, flexibility, and pressure handling capabilities.

Benefits of 4% Double Wall Corrugated Pipes

The adoption of 4% double wall corrugated pipes has led to numerous advantages in various applications

- Durability and Strength With their double wall design, these pipes are resistant to cracks and damage from heavy loads, making them ideal for underground installations and stormwater management.

- Lightweight and Easy Handling The reduced weight, thanks to the corrugated design, facilitates easy transportation and installation, which helps to decrease labor costs.

- Cost-Effectiveness The longevity and minimal maintenance requirements of these pipes translate to significant cost savings over time, making them an economical choice for projects.

- Versatility These pipes are suitable for a range of applications, including drainage systems, wastewater management, and even industrial use. They can handle various fluid types, from stormwater to industrial wastewater.

Conclusion

As the demand for efficient and sustainable construction materials continues to grow, the factories producing 4% double wall corrugated pipes play a critical role in meeting these needs. Their advanced manufacturing processes, coupled with the inherent benefits of the pipes, position them as leaders in the industry. Understanding the capabilities and advantages of these pipes is essential for engineers, contractors, and project managers looking to implement robust and reliable piping solutions in their projects. As technology advances, we can anticipate further innovations in piping materials and manufacturing processes, enhancing the value of 4% double wall corrugated pipes in the marketplace.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025