Dec . 11, 2024 12:15 Back to list

48 inch hdpe pipe cost product

Understanding the Cost of 48-Inch HDPE Pipe A Comprehensive Overview

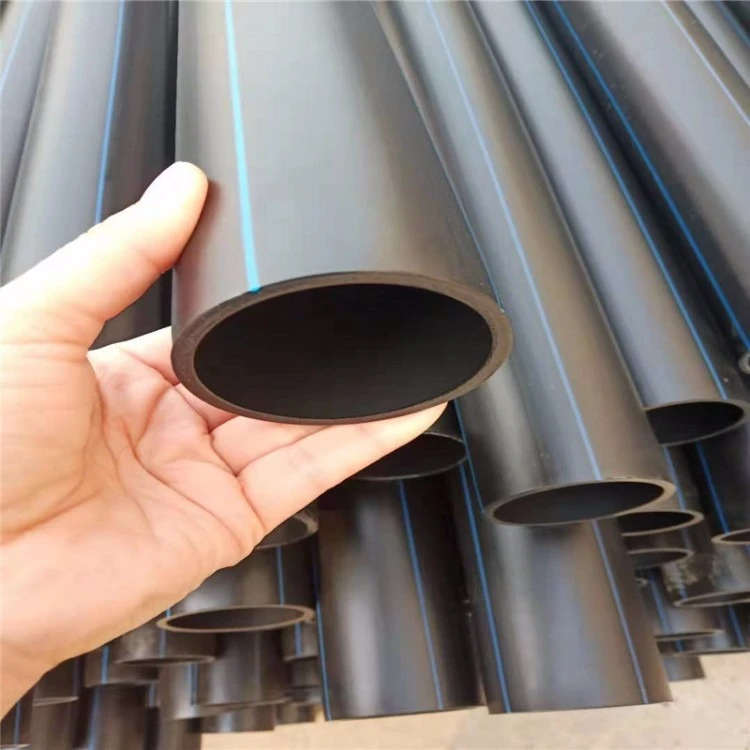

High Density Polyethylene (HDPE) pipes have become a popular choice in various industries due to their superior strength, flexibility, and resistance to corrosion. One of the most commonly used sizes of HDPE pipe is the 48-inch diameter. This article aims to provide an in-depth analysis of the costs associated with 48-inch HDPE pipes, including factors affecting pricing, benefits of using HDPE, and common applications.

The Basics of HDPE Pipe

HDPE pipes are manufactured from high-density polyethylene resin, offering numerous advantages over traditional materials such as steel and PVC. The lightweight nature of HDPE simplifies handling and installation. Moreover, HDPE pipes are known for their longevity, with lifespans that can exceed 50 years when properly maintained. These attributes make HDPE pipes ideal for various applications, including water supply, drainage systems, and industrial purposes.

Cost Factors for 48-Inch HDPE Pipe

Several factors influence the cost of 48-inch HDPE pipes. Understanding these can help consumers and industry professionals make informed purchasing decisions.

1. Material Quality The quality of the resin used in the production of HDPE pipes significantly impacts the cost. Higher-grade materials with better performance characteristics generally result in higher prices.

2. Manufacturing Process The complexity of the manufacturing methods can also affect pricing. Advanced technologies that enhance the durability and performance of the pipes may come with a higher initial cost.

3. Length and Pressure Rating The length of the pipe and its pressure rating can influence the overall cost. Longer lengths may offer lower prices per unit but can incur higher shipping costs. Similarly, pipes designed for higher pressure applications are typically more expensive.

4. Market Demand and Availability Market dynamics, including supply chain factors and regional demand, can cause fluctuations in pricing. In times of high demand—such as during infrastructure projects—the cost of HDPE pipes may increase.

5. Installation and Labor Costs While the material cost is significant, installation costs should not be overlooked. HDPE pipes require specific installation techniques, and the expertise of the labor force can affect the overall project budget.

The Cost Range

48 inch hdpe pipe cost product

On average, the cost of 48-inch HDPE pipe can range from $15 to $30 per foot. However, this is a general estimate, and actual prices can vary based on the mentioned factors. Additional expenses may include fittings, connectors, and installation, which should be factored into the total project cost.

Benefits of Choosing HDPE Pipe

1. Durability HDPE pipes are known for their resilience against cracking, corrosion, and environmental stress. This durability translates to lower maintenance costs over the lifetime of the pipe.

2. Eco-Friendly HDPE is a recyclable material, contributing to environmental sustainability. Using HDPE pipes can enhance the eco-friendliness of infrastructural projects.

3. Flexibility The ability of HDPE pipes to bend and curve makes them suitable for various installations. This flexibility can lead to significant savings in installation time and labor.

4. Leak-Free Joints HDPE pipes can be joined using heat fusion techniques, creating seamless joints that significantly reduce the risk of leaks.

Common Applications

48-inch HDPE pipes are widely used in multiple sectors, including

- Water Distribution Serving as pipelines for municipal water supplies. - Sewage Disposal Used in waste management systems to transport sewage and stormwater. - Industrial Applications Implemented in various industries for transporting chemicals and other liquids.

Conclusion

The cost of 48-inch HDPE pipe can vary widely based on several factors, including material quality, market demand, and installation complexities. However, their long-term benefits—such as durability, environmental sustainability, and flexibility—make them an attractive option for many applications. For those undertaking projects involving large-scale piping solutions, investing in high-quality HDPE pipes can yield significant returns over time, ultimately leading to more efficient and sustainable operations.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025