Nov . 21, 2024 08:31 Back to list

48 hdpe pipe for sale manufacturer

Understanding the Importance of 48% HDPE Pipe A Comprehensive Overview for Buyers

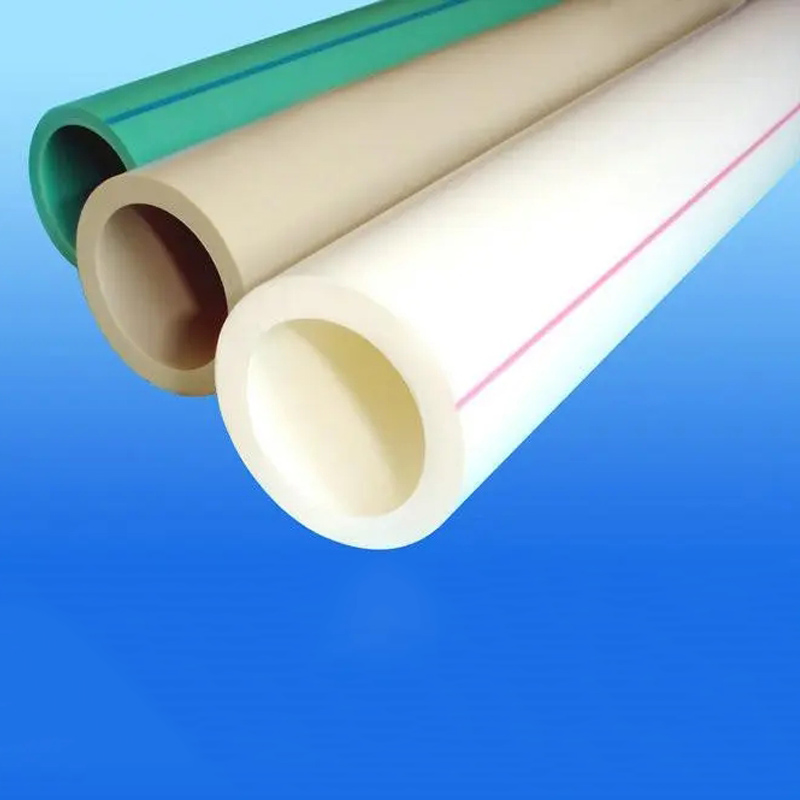

When it comes to industrial piping solutions, High-Density Polyethylene (HDPE) pipes are gaining significant traction in various sectors. Among the different specifications available, 48% HDPE pipes stand out due to their unique composition and remarkable properties. This article delves into the relevance of 48% HDPE pipes, their applications, advantages, and why selecting the right manufacturer is crucial for quality assurance.

What Is 48% HDPE Pipe?

48% HDPE pipe is characterized by its density, with 48% signifying a specific ratio of high-density polyethylene utilized in its production. HDPE itself is known for its superior tensile strength and resistance to impact, making it highly favorable for a variety of applications, including water supply, irrigation, sewage systems, and gas distribution. The 48% ratio indicates a formulation designed to maximize performance while considering cost-effectiveness for various uses.

Applications of 48% HDPE Pipe

The versatility of 48% HDPE pipes makes them suitable for multiple industries. Here are some of the key applications

1. Water Distribution HDPE pipes are widely used for potable water distribution due to their non-corrosive nature and minimal leachate. They ensure clean drinking water reaches communities without contamination.

2. Irrigation Systems Agriculture heavily relies on efficient irrigation systems. HDPE pipes are used to transport water across vast agricultural fields, helping farmers maximize their outputs while conserving water.

3. Sewage and Drainage HDPE's resistance to chemicals and robust structure makes it ideal for sewage and drainage applications. These pipes can endure harsh conditions and provide reliable service over many years.

4. Gas Distribution Natural gas companies use HDPE pipes for gas distribution lines. Their durability and safety features ensure reliable transportation of gas without the risks associated with traditional metal pipes, such as corrosion.

5. Industrial Applications Industries that require structured piping solutions for various fluids—be it chemicals, waste, or drainage—prefer HDPE due to its strength and flexibility.

Advantages of 48% HDPE Pipe

The growing popularity of HDPE pipes, specifically the 48% variant, can be attributed to a range of advantages

48 hdpe pipe for sale manufacturer

1. Durability and Longevity HDPE pipes are known for their outstanding resistance to weather, chemicals, and abrasion, leading to longer service life and fewer replacements.

2. Flexibility Unlike rigid pipes, HDPE is flexible, which allows for easier installation in challenging terrains and reduces the risk of breakage during installation and transportation.

3. Cost-Effectiveness 48% HDPE pipes offer an economical solution compared to metal pipes. They are lighter, making transportation and handling more manageable while also reducing installation costs.

4. Environmentally Friendly HDPE pipes are recyclable and have a lower environmental impact compared to traditional piping materials. Their production process emits fewer greenhouse gases, supporting various sustainability initiatives.

5. Smooth Flow The interior surface of HDPE pipes is smooth, leading to reduced friction and allowing for higher flow rates. This characteristic ensures efficient transportation of fluids.

Selecting a Manufacturer

When considering the purchase of 48% HDPE pipes, choosing the right manufacturer is paramount. Buyers should look for manufacturers with

- Reputation and Experience Established companies with a track record in producing high-quality HDPE pipes are more likely to meet industry standards.

- Quality Certifications Manufacturers that comply with ISO and other relevant quality assurance certifications provide assurance of the product's integrity and performance.

- Customization Options Depending on specific project requirements, buyers may need customization in terms of size, thickness, and length. A good manufacturer will offer solutions tailored to customer needs.

- Technical Support An experienced supplier often provides significant technical support, helping buyers understand the best practices for installation and maintenance of the pipes.

Conclusion

48% HDPE pipes represent a significant advancement in the realm of piping solutions due to their unique properties and a wide array of applications. Whether for water distribution, sewage systems, or gas lines, these pipes offer reliability and efficiency. By selecting the right manufacturer, buyers can ensure quality and longevity in their piping systems, contributing to better infrastructure and sustainable practices in their respective industries.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025