Sep . 01, 2024 23:27 Back to list

4 HDPE to PVC Coupling Factory - High-Quality Pipe Fittings Manufacturer

Understanding the Production of 4% HDPE to PVC Couplings A Factory Perspective

In the world of plumbing and construction, the need for durable and efficient piping systems is paramount. At the heart of these systems lie couplings, which play a critical role in connecting different types of pipes. One specific type that has garnered attention in recent years is the 4% High-Density Polyethylene (HDPE) to Polyvinyl Chloride (PVC) coupling. This article explores the manufacturing process, benefits, and applications of this coupling from a factory perspective.

The Manufacturing Process

The production of 4% HDPE to PVC couplings begins with the selection of high-quality raw materials. HDPE is known for its strength, flexibility, and resistance to chemicals, making it an ideal choice for coupling production. The incorporation of 4% into HDPE enhances its overall performance, ensuring that the couplings maintain their structural integrity under varying environmental conditions.

The manufacturing process involves several key steps

1. Material Preparation The first stage involves preparing the HDPE and PVC materials. The HDPE is typically pelletized and then mixed with a specific percentage of PVC to achieve the desired durability and flexibility.

2. Extrusion The prepared materials are then fed into an extruder, where they are melted and formed into a continuous profile. The extruder applies heat and pressure to ensure that the materials blend well, leading to a homogeneous mixture.

3. Molding After extrusion, the molten material is transferred to molds where it is shaped into the desired coupling design. This phase is critical as it determines the coupling's final dimensions and features, such as internal threads or barbs for secure fitting.

4. Cooling and Finishing Once molded, the couplings undergo a cooling process accompanied by trimming and finishing steps. This ensures that each piece meets industry standards and is free from defects.

5. Quality Control Before packaging, each coupling is subjected to rigorous quality control tests to check for dimensional accuracy, strength, and resistance to pressure. This step is vital to ensure reliability and safety in applications.

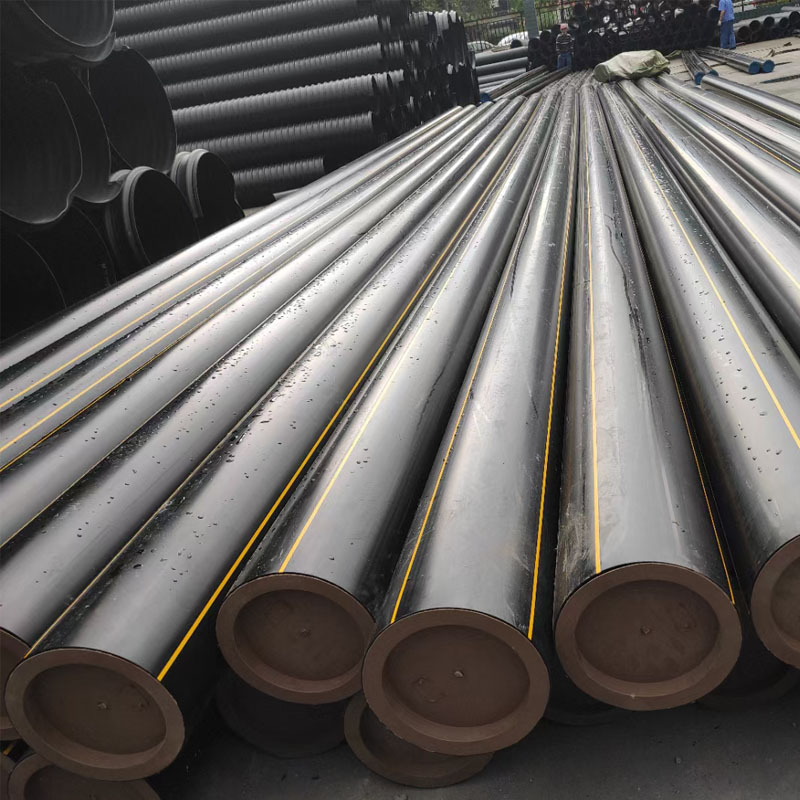

4 hdpe to pvc coupling factory

Benefits of 4% HDPE to PVC Couplings

The integration of 4% HDPE in these couplings offers several advantages

- Durability The addition of PVC enhances the overall strength and lifespan of the coupling, making it resistant to wear and tear, as well as environmental factors such as UV radiation and moisture.

- Corrosion Resistance Both HDPE and PVC are resistant to corrosion, allowing for their use in various applications, including water supply systems, sewage, and drainage.

- Cost-Effectiveness Manufacturing HDPE to PVC couplings is fairly cost-effective due to the efficient production processes. Moreover, their longevity reduces maintenance and replacement costs.

- Versatility These couplings can be utilized in a wide range of applications across different sectors, including residential, commercial, and industrial environments.

Applications

The versatility of 4% HDPE to PVC couplings makes them suitable for various applications. They are commonly used in plumbing systems, irrigation, and even in chemical processing. Their ability to withstand high pressures and harsh chemicals positions them as a reliable choice for both above-ground and underground installations.

Conclusion

In conclusion, the production of 4% HDPE to PVC couplings represents a significant advancement in piping technology. By leveraging the strengths of both materials, manufacturers can provide efficient and durable solutions for a multitude of applications. As industry demands evolve, these couplings will continue to play a pivotal role in the development of sustainable and resilient piping systems. The ongoing commitment to quality in manufacturing processes ensures that these couplings meet the high standards necessary for modern infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025