Dec . 29, 2024 18:42 Back to list

3 4 ppr pipe in mm manufacturer

Understanding 3% and 4% PPR Pipe in Millimeters A Comprehensive Guide for Manufacturers

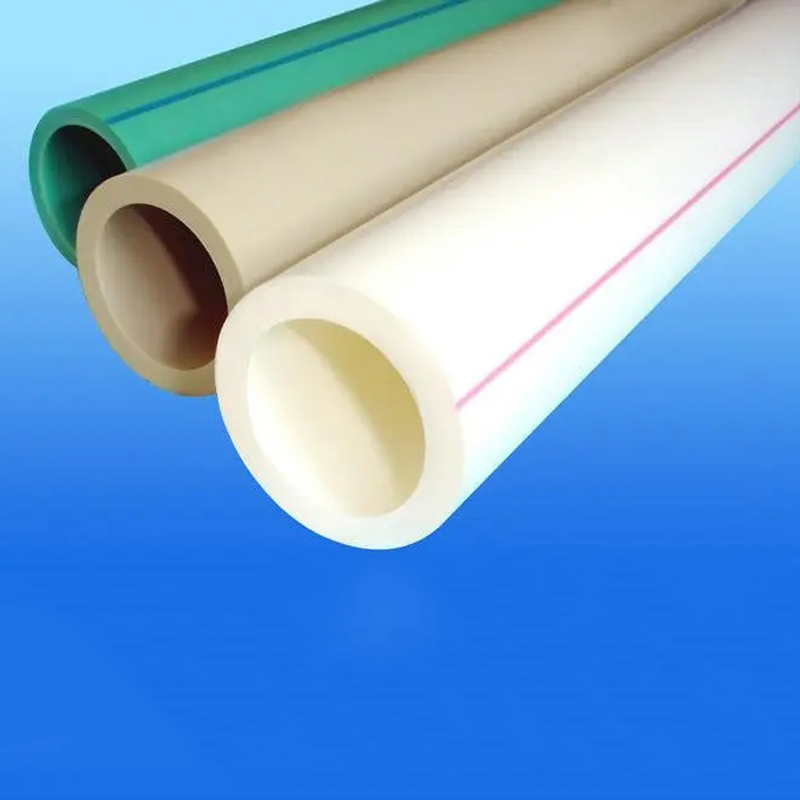

PPR pipes, or Polypropylene Random Copolymer pipes, are becoming increasingly popular in modern plumbing and piping systems. Known for their durability, corrosion resistance, and lightweight nature, these pipes are ideal for various applications including hot and cold water supply, as well as heating systems. Among the varying specifications available in the market today, the 3% and 4% PPR pipes in millimeters have gained notable attention from manufacturers and construction professionals alike.

What are PPR Pipes?

PPR pipes are a type of thermoplastic pipe made from polypropylene, and they are available in different grades based on their intended application. The main characteristics of PPR pipes include their high chemical resistance, low thermal conductivity, and ease of installation. One of the significant advantages is their ability to withstand high temperatures and pressure, which makes them suitable for both hot water and cold water applications.

Introduction to 3% and 4% Specifications

When we refer to 3% and 4% PPR pipes, we typically discuss their pressure ratings and wall thicknesses that adhere to specific industry standards, thereby influencing their performance in various scenarios. The percentage indicates the material composition or the level of reinforcement suitable for specific tasks.

1. 3% PPR Pipe Generally, the 3% PPR pipe tends to be designed for medium pressure applications. This specification is beneficial for installations that necessitate a balance between flexibility and strength. For instance, in residential water supply systems, 3% PPR pipes can efficiently handle the pressures typically encountered without compromising the integrity of the system.

2. 4% PPR Pipe In contrast, the 4% PPR pipe is engineered for higher pressure applications, providing superior strength and resilience. These pipes are usually employed in industrial applications, heating systems, and other scenarios where higher durability is required. The enhanced material composition allows for a significant increase in pressure thresholds, making them ideal for more demanding conditions.

Manufacturing Considerations

3 4 ppr pipe in mm manufacturer

For manufacturers of 3% and 4% PPR pipes, several factors must be considered to ensure the final product meets required standards

1. Quality Raw Materials The quality of polypropylene used during production plays a crucial role in the pipes' performance. Manufacturers must source high-grade materials to ensure longevity and reliability.

2. Precise Manufacturing Processes The extrusion process must be approached with precision. Different temperatures, speeds, and pressures can greatly affect the wall thickness and overall stability of the pipes. Continuous quality control during manufacturing ensures that the pipes maintain the necessary specifications.

3. Standard Compliance Compliance with international standards (such as ISO and ASTM) is vital for manufacturers. This does not only increase trust among consumers but also ensures the pipes are fit for their intended applications.

4. Testing and Certifications Routine testing, including pressure tests, burst tests, and thermal tests, must be conducted to verify the performance characteristics of the pipes. Certification from recognized bodies enhances product credibility in the market.

Market Applications

The versatility of 3% and 4% PPR pipes enables their use in various applications. 3% pipes are commonly utilized in residential plumbing, irrigation, and HVAC systems, while 4% pipes are often found in commercial plumbing, industrial installations, and centralized heating systems. Their lightweight nature and excellent jointing capabilities (using heat fusion) make them easy to transport and install, further solidifying their appeal in the construction industry.

Conclusion

In summary, 3% and 4% PPR pipes represent a significant advancement in plumbing technology. Manufacturers must adhere to stringent quality and testing protocols to ensure these pipes meet the evolving demands of modern construction and industrial applications. With the growing trend toward sustainable and efficient piping solutions, the future of PPR pipes appears promising, marking them as a favored choice for builders and contractors worldwide. As the market continues to evolve, investment in innovative manufacturing practices will be key to maintaining competitiveness in the field.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025