Nov . 23, 2024 09:07 Back to list

2 ppr pipe factory

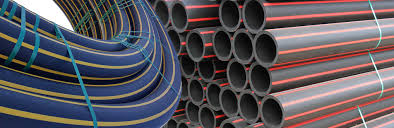

Exploring the World of 2% PPR Pipe Factories

In today’s modern construction and plumbing industry, the need for durable and reliable piping solutions has never been greater. Among the myriad options available, Polypropylene Random Copolymer (PPR) pipes have emerged as a popular choice, especially in regions where high-quality plumbing materials are essential. This article will delve into the significance of 2% PPR pipe factories, their production processes, and the benefits they offer.

Exploring the World of 2% PPR Pipe Factories

The manufacturing process of 2% PPR pipes involves several critical steps. It begins with the procurement of high-quality raw materials, which are meticulously tested to meet industry standards. The polymers are then melted and extruded into pipes of various diameters and lengths. Throughout this process, quality control measures are in place to inspect for defects and confirm that the pipes can withstand the industry's pressure requirements.

2 ppr pipe factory

One of the standout advantages of 2% PPR pipes produced in specialized factories is their longevity. Unlike traditional materials such as PVC or metal pipes, PPR pipes do not corrode or rust over time. This attribute significantly extends their lifespan, making them a more cost-effective solution for consumers in the long run. Additionally, PPR pipes are lightweight, which simplifies handling and installation, reducing labor costs.

Another notable benefit of 2% PPR pipes is their environmental friendliness. They are fully recyclable, and their production involves lower energy consumption compared to other piping materials. This aspect resonates well with the growing global emphasis on sustainability and environmental responsibility within the construction industry.

The demand for 2% PPR pipes continues to rise, particularly in regions experiencing rapid urbanization and infrastructural development. As more construction projects seek to implement reliable and efficient plumbing systems, the role of PPR pipe factories becomes increasingly vital. These facilities not only contribute to the economy but also play a critical role in enhancing the quality of life for communities by providing access to safe and effective water supply solutions.

In conclusion, 2% PPR pipe factories are instrumental in the supply of high-quality plumbing systems that meet modern needs. Their commitment to excellence in production and adherence to industry standards ensure that consumers receive durable products that enhance both functionality and sustainability. As the construction industry evolves, the influence of these specialized factories will undoubtedly continue to grow, paving the way for innovative piping solutions in the future.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025