Dec . 26, 2024 02:54 Back to list

2 hdpe to pvc coupling products

Understanding the Transition from 2% HDPE to PVC Coupling Products

In the evolving landscape of manufacturing and materials technology, coupling products have gained significant attention for their versatility and resilience. This article delves into the use of 2% High-Density Polyethylene (HDPE) to Polyvinyl Chloride (PVC) coupling products, examining their benefits, applications, and the transition process.

Overview of HDPE and PVC

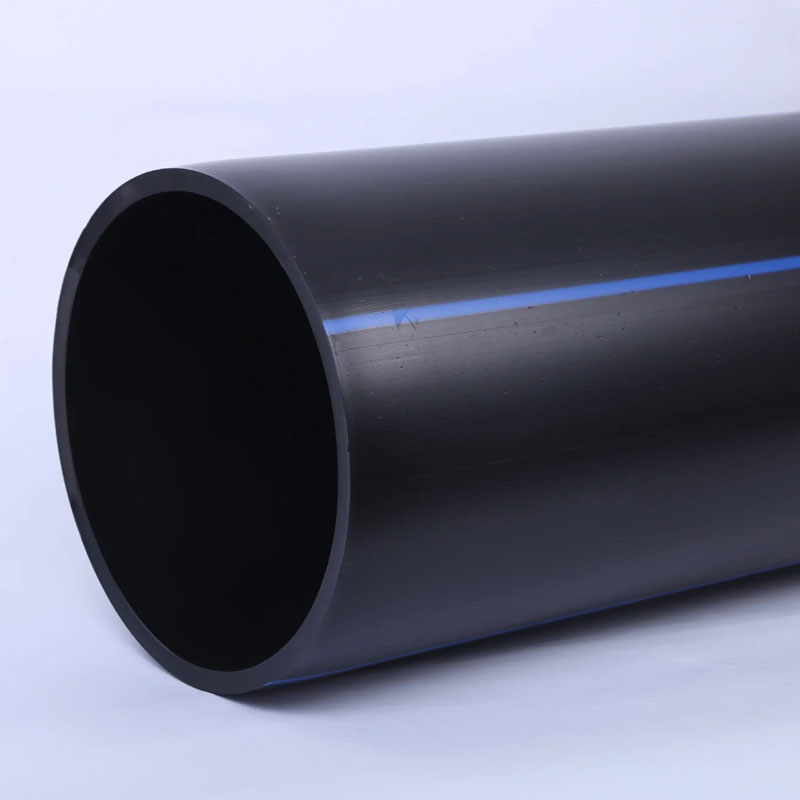

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its high strength-to-density ratio. It is widely used in various applications, particularly in packaging, containers, and piping systems due to its durability, resistance to impact, and low moisture absorption. Conversely, Polyvinyl Chloride (PVC) is another popular plastic that offers remarkable chemical resistance and high rigidity. It is frequently utilized in construction materials, medical devices, and electrical insulation.

The choice between HDPE and PVC, especially in coupling applications, often hinges on the specific needs of the project, including flexibility, weight, chemical exposure, and temperature resilience.

The 2% HDPE to PVC Transition

The integration of a 2% concentration of HDPE into PVC coupling products reflects manufacturers' efforts to enhance product performance. The transition from a purely PVC coupling to one that incorporates 2% HDPE presents a multitude of benefits. The slight inclusion of HDPE can provide improved impact resistance, lower weight, and increased adaptability in diverse temperatures, making it an attractive option for manufacturers and consumers alike.

Benefits of 2% HDPE in PVC Couplings

1. Enhanced Durability The addition of 2% HDPE improves the overall durability of PVC couplings. It enhances resistance to wear and tear, making products less prone to cracking and breaking under stress or extreme environmental conditions.

2. Improved Flexibility While PVC is known for its rigidity, incorporating HDPE enhances the flexibility of the coupling products. This feature allows for easier installation and adjustment during use, catering to varying application needs.

2 hdpe to pvc coupling products

3. Weight Reduction The incorporation of HDPE contributes to a lighter product while maintaining strength. This reduction in weight can lead to lower transportation costs and easier handling during installation processes.

4. Cost-Effectiveness Although the addition of HDPE might slightly increase production costs, the resultant product longevity and durability can lead to lower maintenance and replacement expenses over time.

5. Environmental Considerations As sustainability becomes a priority in manufacturing, using HDPE—often derived from recycled materials—can appeal to environmentally conscious consumers. This transition aids in reducing the carbon footprint associated with traditional PVC products.

Applications of 2% HDPE to PVC Coupling Products

The applicability of 2% HDPE to PVC coupling products spans multiple industries. In plumbing, these couplings can connect pipes efficiently while withstanding different pressures and temperatures, thereby preventing leaks and fostering reliability.

In the electrical sector, the enhanced properties can ensure that electrical conduits remain intact even in adverse conditions. Moreover, in construction, these couplings can serve as vital connectors in various structural applications, such as in walls, roofs, and foundations.

Conclusion

The evolution from using conventional PVC to incorporating 2% HDPE in coupling products highlights significant advancements in material science. As manufacturers continue to innovate, combining the strengths of both HDPE and PVC paves the way for products that meet the demands of modern applications.

By prioritizing durability, functionality, and environmental considerations, the use of 2% HDPE to PVC coupling products is set to play a pivotal role in the future of manufacturing, ensuring that industries can rely on high-quality materials that stand the test of time. As technology progresses, the potential for further enhancements remains vast, promising exciting developments in coupling solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025