Nov . 25, 2024 05:53 Back to list

High-Quality 2% HDPE Couplings from Reliable Manufacturing Sources

Understanding the Role of 2% HDPE Coupling Factories in Modern Manufacturing

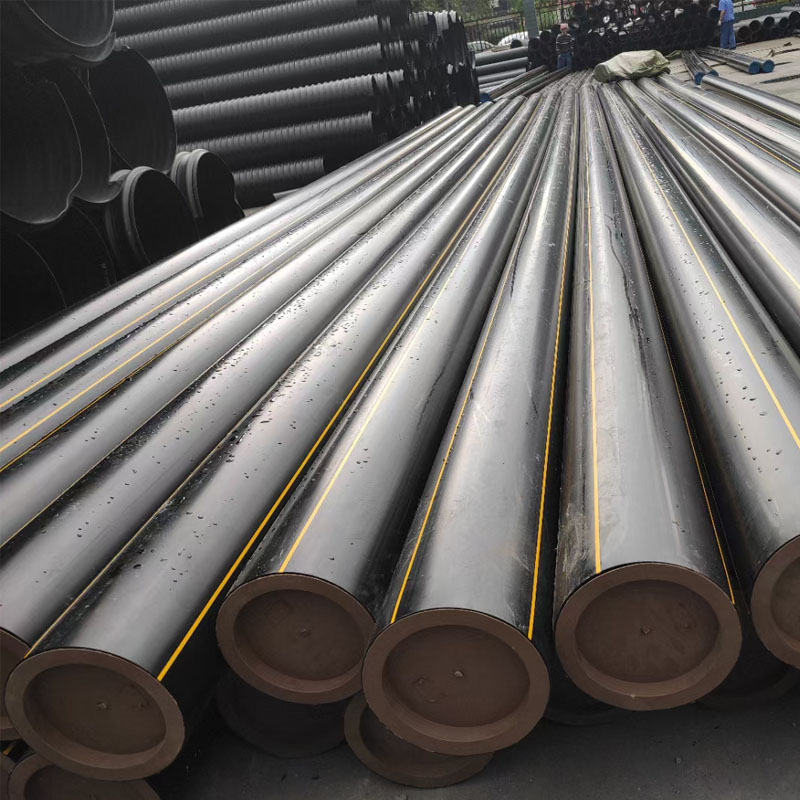

High-Density Polyethylene (HDPE) has become an essential material in various industries due to its strength, durability, and resistance to chemicals and moisture. Among the many applications of HDPE, the production of couplings is particularly noteworthy. Couplings serve as vital connectors in piping systems, ensuring the seamless transfer of liquids and gases. In this context, factories specializing in producing 2% HDPE couplings play a significant role in manufacturing efficiency and product reliability.

Understanding the Role of 2% HDPE Coupling Factories in Modern Manufacturing

The manufacturing process of 2% HDPE couplings involves advanced techniques that ensure precision and quality control. Factories utilize state-of-the-art machinery and technologies to extrude and mold HDPE into coupling shapes that meet specific industry standards. The combination of automation and skilled craftsmanship allows these factories to produce couplings at a scale that meets the demanding needs of the market while maintaining consistency in quality.

2 hdpe coupling factory

In terms of environmental impact, HDPE is a more sustainable choice compared to other materials. Its recyclability and lower life cycle energy requirements make it an attractive option for manufacturers looking to lessen their environmental footprint. Many 2% HDPE coupling factories are adopting eco-friendly practices, including using recycled HDPE in their production processes. This not only helps reduce waste but also appeals to environmentally conscious consumers and businesses.

Moreover, 2% HDPE coupling factories play a pivotal role in driving innovation within the industry. Manufacturers are continually experimenting with new formulations and processes to enhance the performance and applications of HDPE couplings. For instance, the addition of various additives can improve UV resistance or increase the bonding capabilities with other materials. This innovation is crucial as industries evolve and require specialized solutions that traditional materials cannot provide.

Collaboration between 2% HDPE coupling factories and designers, architects, and engineers is also essential for creating products that meet specific project requirements. By engaging with these stakeholders early in the design process, factories can tailor their products to fit unique applications, ensuring that the couplings perform optimally in their intended environments.

In conclusion, 2% HDPE coupling factories are more than just production facilities; they are vital contributors to the manufacturing ecosystem. By providing innovative, durable, and environmentally friendly coupling solutions, these factories are supporting various industries and promoting sustainable practices. As the demand for reliable and efficient piping solutions continues to grow, the significance of these factories will only increase, reinforcing their role as indispensable partners in modern manufacturing. Investing in high-quality 2% HDPE couplings will not only enhance the performance of systems but also foster a more sustainable future in industrial practices.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025