Sep . 04, 2024 14:41 Back to list

High-Quality HDPE to PVC Couplings Manufacturer | Durable and Reliable Solutions

Understanding the 2% HDPE to PVC Coupling Manufacturer

When it comes to plumbing and construction, the coupling of different materials can pose significant challenges. One such challenge arises when working with high-density polyethylene (HDPE) and polyvinyl chloride (PVC). These two materials, while popular in their respective applications, require careful consideration during coupling processes to ensure lasting connections that can withstand environmental conditions. This is where coupling manufacturers come into play, particularly those specializing in translating the nuances of HDPE to PVC couplings.

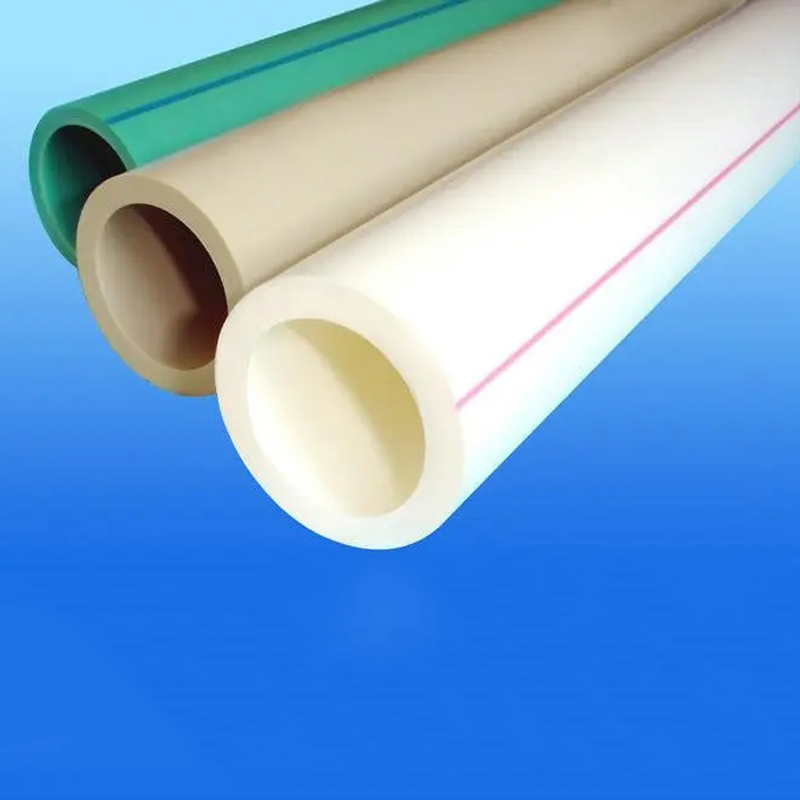

The Materials HDPE and PVC

High-density polyethylene (HDPE) is renowned for its durability, resistance to chemicals, and flexibility. It is commonly used in piping systems, agricultural applications, and even packaging due to its ability to withstand various environmental factors. On the other hand, polyvinyl chloride (PVC) is widely utilized in plumbing and construction for its rigidity, ease of installation, and cost-effectiveness. However, the differences in chemical composition and physical properties between HDPE and PVC mean that manufacturers must develop specific couplings to ensure compatibility and reliability.

The Importance of Specialized Couplings

The coupling process between HDPE and PVC involves more than simply joining two pipes. It requires a precise understanding of both materials, including their expansion and contraction rates, chemical resistance, and mechanical strength. Manufacturers specializing in 2% HDPE to PVC couplings focus on creating products that can seamlessly connect these two materials while maintaining the integrity of the pipe systems.

2 hdpe to pvc coupling manufacturer

These specialized couplings often feature unique designs, such as transition fittings or compression fittings, which compensate for the differing characteristics of HDPE and PVC. For instance, a transition fitting may include rubber seals that accommodate movement and prevent leaks. Similarly, compression fittings can provide a secure, adjustable fit that remains watertight under varying pressure conditions.

Quality Control and Standards

A reputable 2% HDPE to PVC coupling manufacturer prioritizes quality control in its production process. This includes rigorous testing of materials to ensure they meet industry standards. Certifications from organizations such as ASTM International and the American National Standards Institute (ANSI) provide additional assurance of quality and safety.

Manufacturers also engage in regular product evaluations and testing for durability, pressure resistance, and long-term performance. This attention to detail helps ensure that end-users receive couplings that will perform reliably for many years, even in challenging conditions.

Conclusion

As construction and plumbing projects increasingly require the integration of various materials, the role of specialized coupling manufacturers becomes ever more critical. The 2% HDPE to PVC coupling represents a vital component in ensuring the efficiency and longevity of installations that use both materials. Understanding the intricacies of these couplings and choosing a manufacturer with expertise and commitment to quality can significantly impact the success of construction and plumbing endeavors. Ultimately, investing in reliable couplings is an investment in the strength and durability of any infrastructure, helping to prevent leaks and ensuring peace of mind for homeowners and professionals alike.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025