Nov . 02, 2024 03:23 Back to list

1 2 ppr pipe factories

The Ubiquity of 1% 202 PVC Pipe Factories A Critical Analysis

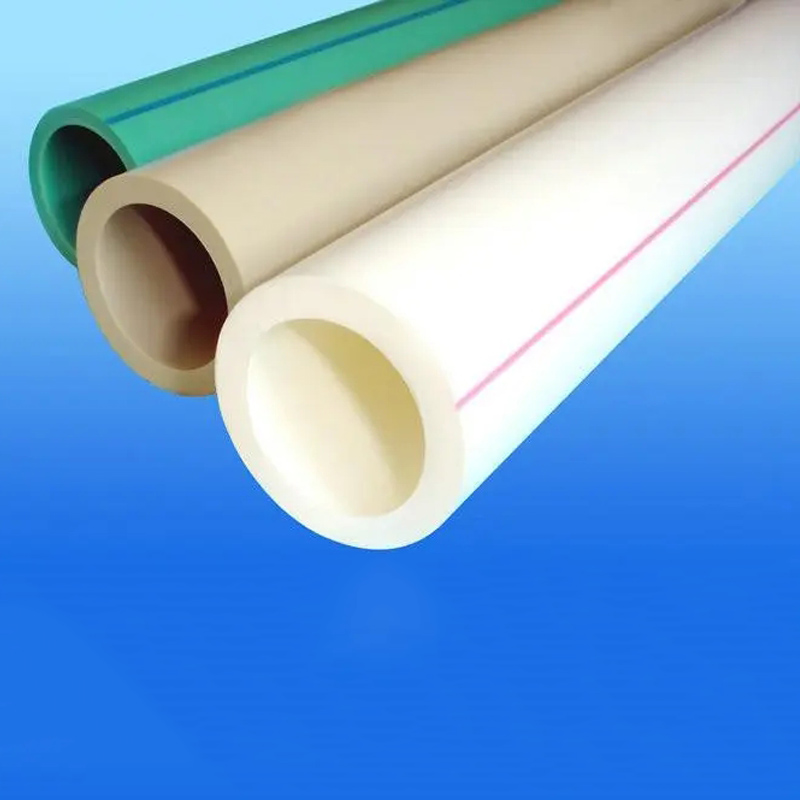

In the intricate world of construction and plumbing, the significance of materials cannot be overstated. One such material that has gained considerable traction is the PVC pipe, particularly the 1% 202 variant. These pipes have become staples in various industries due to their durability, cost-effectiveness, and versatility. With the increasing demand for reliable plumbing solutions, the emergence of 1% 202 PVC pipe factories has transformed the landscape of manufacturing and distribution in this sector.

The Rise of 1% 202 PVC Pipes

1% 202 PVC pipes are characterized by their composition, which includes specific additives that enhance their performance. These pipes boast impressive resistance to corrosion, impact, and harsh chemicals, making them suitable for a wide range of applications, from residential plumbing to industrial use. The demand for these pipes has surged in recent years, driven by the growth of urban infrastructure projects and the need for reliable water supply systems.

The proliferation of 1% 202 PVC pipe factories has played a crucial role in meeting this demand. These factories are strategically located in various regions to ensure quick delivery and reduced transportation costs. As the market for plumbing solutions continues to expand, the establishment of such factories has not only contributed to economic growth but has also created numerous job opportunities.

Environmentally Friendly Practices

Another pressing concern in today’s manufacturing landscape is sustainability. Many 1% 202 PVC pipe factories are now adopting environmentally friendly practices to minimize their ecological footprint. From sourcing raw materials responsibly to implementing recycling measures, these facilities are becoming more aware of their impact on the environment.

1 2 ppr pipe factories

For instance, some factories have begun utilizing solar energy for their production processes, significantly reducing carbon emissions. Additionally, innovations in manufacturing techniques have allowed for the production of pipes with lower energy consumption. As consumers increasingly prioritize sustainable products, these efforts position factories favorably in the market.

Quality Control and Standards

Quality control is paramount in the manufacturing of PVC pipes. The establishment of 1% 202 PVC pipe factories comes with the responsibility of adhering to national and international standards. Rigorous testing procedures ensure that the pipes produced can withstand the pressures and conditions they will encounter in practical applications. This commitment to quality reinforces consumer confidence and encourages the adoption of PVC piping solutions.

These factories often collaborate with industry experts and regulatory bodies to ensure compliance with the latest standards. Continuous improvement and investment in research and development are crucial for these facilities to maintain their competitive edge.

Conclusion

In summary, the emergence of 1% 202 PVC pipe factories marks a significant development in the plumbing and construction industries. These facilities are essential for producing high-quality, durable, and cost-effective piping solutions that meet the growing demands of modern infrastructure. By focusing on environmentally friendly practices and stringent quality control measures, these factories not only ensure the availability of reliable products but also contribute positively to sustainable development. As the urban landscape continues to evolve, the role of 1% 202 PVC pipe factories will undoubtedly remain vital in shaping the future of plumbing and construction solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025