Dec . 04, 2024 10:43 Back to list

10mm pvc pipe factory

The Growing Importance of 10mm PVC Pipe Factories

In today’s world, where infrastructure and construction play pivotal roles in economic development, the demand for high-quality materials has surged. Among these materials, polyvinyl chloride (PVC) pipes have gained immense popularity due to their versatility, durability, and cost-effectiveness. Among various sizes, 10mm PVC pipes have emerged as a crucial component in numerous applications, leading to the rise of specialized factories focused on their production.

What Are 10mm PVC Pipes?

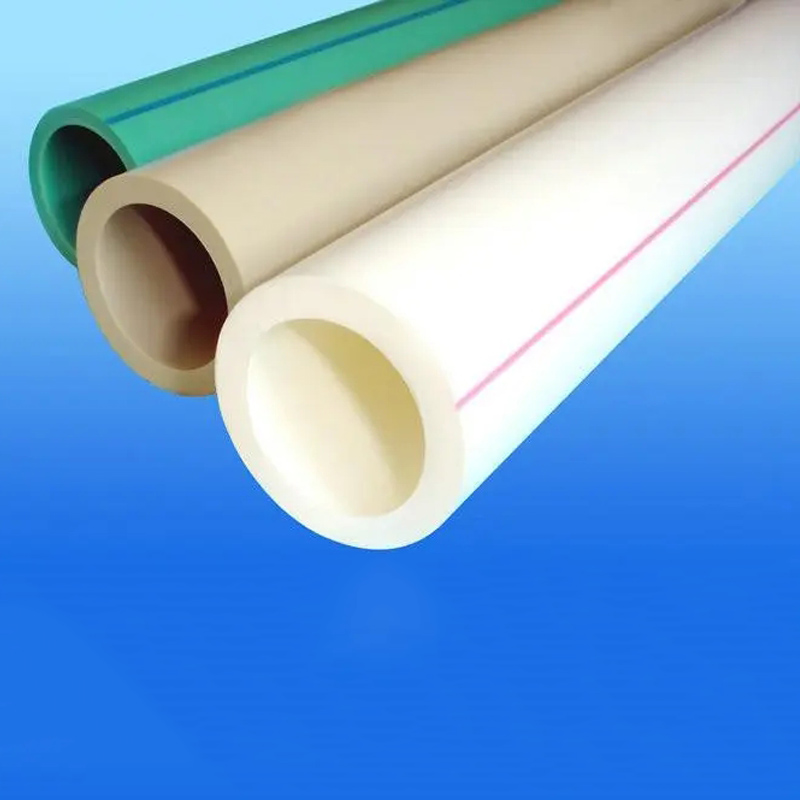

10mm PVC pipes are small-diameter pipes often used in plumbing, irrigation systems, and electrical conduits. Their compact size makes them particularly suitable for applications that require precise fluid flow management, tight spaces, and lightweight solutions. They are non-toxic, resistant to corrosion, and can handle high pressure, making them ideal for transporting water and other fluids under diverse conditions.

The Market Demand

The growing demand for 10mm PVC pipes can be attributed to several factors. Firstly, the construction industry is booming, especially in developing nations. As urbanization continues to escalate, there is a crucial need for efficient water supply systems and reliable drainage solutions. PVC pipes are brilliant candidates for these applications due to their longevity and maintenance-free nature.

Secondly, the agricultural sector is increasingly leveraging sophisticated irrigation techniques to enhance crop yields. 10mm PVC pipes are often employed in drip irrigation systems, where precise water delivery is essential to conserve water and ensure optimal plant growth. Their lightweight nature allows for easy installation and adjustment, making them a preferred choice among farmers.

The Role of 10mm PVC Pipe Factories

Dedicated factories producing 10mm PVC pipes play a vital role in meeting the rising demand. These facilities utilize advanced manufacturing techniques that prioritize efficiency and sustainability. The production process often involves the extrusion of PVC materials, which are then formed into specific sizes and shapes under controlled conditions to maintain quality.

10mm pvc pipe factory

In addition to traditional manufacturing, many factories are embracing automation and digital technologies. This allows for better quality control, reduced labor costs, and increased output. Factories equipped with state-of-the-art machinery can produce a higher volume of pipes while adhering to international standards and regulations.

Quality Assurance and Standards

One of the key challenges faced by 10mm PVC pipe factories is ensuring consistent quality. Because these pipes are integral to vital systems like water supply and drainage, any defects could lead to significant issues. To address this, factories often implement rigorous quality assurance protocols, including regular testing of raw materials and finished products. Certifications from recognized standards organizations can enhance a factory’s reputation and appeal to potential clients.

Environmental Considerations

As environmental concerns become increasingly pressing, many PVC pipe factories are focusing on sustainable practices. This includes recycling PVC waste generated during production and using eco-friendly additives. Moreover, there is a growing market for recycled PVC pipes, making sustainability a lucrative aspect of the industry. Factories are now tasked with not only producing pipes but also contributing to the circular economy.

Future Prospects

Looking ahead, the future for 10mm PVC pipe factories appears bright. The global shift toward smart cities and sustainable development will only amplify the demand for high-quality piping solutions. Factories that adapt to technological advancements and focus on sustainable practices will likely thrive in this evolving market.

In conclusion, 10mm PVC pipe factories are becoming increasingly significant in the construction and agricultural sectors. Their ability to meet rising demand with quality products while addressing environmental considerations positions them as vital players in the materials industry. As society continues to develop and innovate, these factories will undoubtedly play a crucial role in shaping the infrastructure of tomorrow.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025