Dec . 13, 2024 08:44 Back to list

Top 10 Manufacturers of HDPE Corrugated Pipes for Various Applications

The Growing Significance of HDPE Corrugated Pipe Factories in Modern Infrastructure

In recent years, the construction and infrastructure sectors have been rapidly evolving, seeking materials that offer both durability and cost-efficiency. Among these innovations is High-Density Polyethylene (HDPE) corrugated pipe, which has emerged as a preferred choice for various applications, including drainage, stormwater management, and even sewage systems. With the demand for sustainable and resilient building materials on the rise, the importance of HDPE corrugated pipe factories has become increasingly significant.

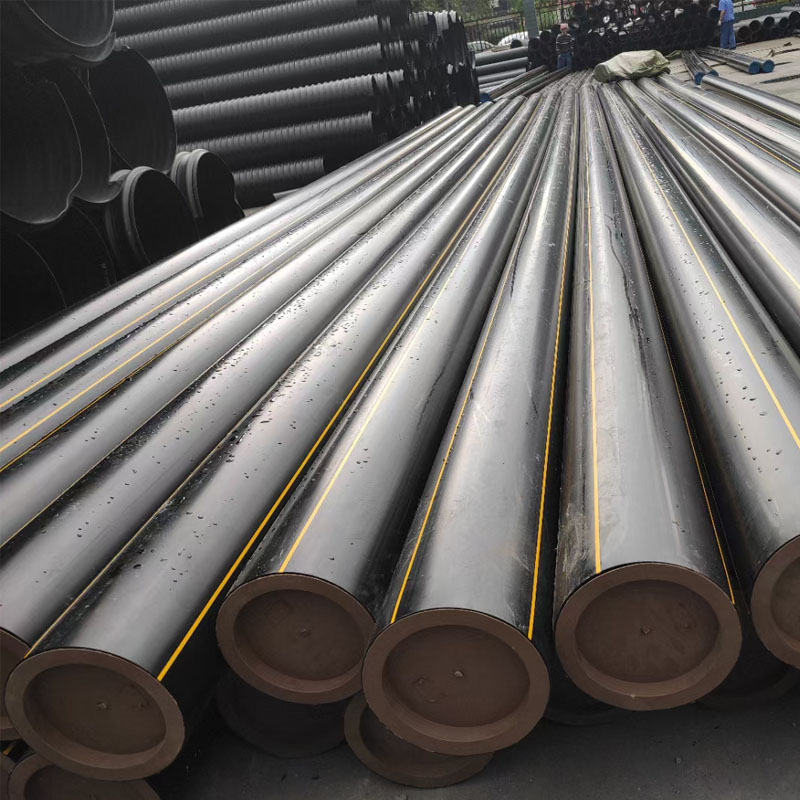

What is HDPE Corrugated Pipe?

HDPE corrugated pipes are manufactured from high-density polyethylene, a type of plastic known for its high strength-to-density ratio. The “corrugated” design involves a series of alternating ridges and grooves that lend the pipe its unique structural integrity, allowing it to withstand substantial external pressures, soil movement, and extreme weather conditions. This characteristic makes HDPE pipes an ideal solution for underground applications, as they can effectively manage fluid flow while resisting deformation.

Environmental Benefits

One of the primary reasons for the burgeoning popularity of HDPE corrugated pipe is its eco-friendly profile. The production of HDPE involves processes that are less harmful to the environment compared to traditional materials like concrete or metal. HDPE is 100% recyclable, which means that end-of-life pipes can be repurposed, thereby reducing landfill waste. Additionally, the lightweight nature of HDPE means lower transportation costs and reduced carbon footprints during the logistics process.

Cost-Efficiency and Installation

Cost-efficiency is another significant advantage that HDPE corrugated pipes have over their counterparts. The manufacturing process of these pipes is streamlined, leading to lower production costs. Furthermore, their lightweight nature makes handling and installation more straightforward, requiring less labor and machinery. This means that construction companies can save both time and money when working with HDPE corrugated pipes.

10 hdpe corrugated pipe factories

Durability and Longevity

HDPE pipes exhibit excellent resistance to corrosion, chemicals, and UV radiation, ensuring a longer lifecycle compared to traditional materials. The durability of these pipes translates to fewer replacements and repairs, contributing to lower long-term operational costs for municipalities and construction firms. In environments prone to flooding or extreme weather, the reliability of HDPE corrugated pipes can make a substantial difference in infrastructure resilience.

Innovations and Technological Advancements

As technology evolves, HDPE corrugated pipe factories are adopting innovative techniques to enhance production efficiency. Advanced manufacturing processes, such as co-extrusion and the incorporation of smart sensors, are being implemented to produce pipes that meet stringent quality standards. These technological advancements help ensure that the pipes remain consistent in performance while also being adaptable to various applications.

Market Trends and Future Outlook

The global demand for HDPE products is on the rise, driven by increased infrastructure development and the need for modern drainage solutions. According to market research, the HDPE pipe market is projected to grow significantly in the coming years due to urbanization and investments in water management systems. This surge in demand underscores the critical role that HDPE corrugated pipe factories will play in the future of construction and infrastructure.

Conclusion

In conclusion, HDPE corrugated pipe factories are at the forefront of modern infrastructure development, offering significant benefits in terms of durability, cost, and environmental impact. As the industry continues to lean towards sustainable practices and innovative materials, the reliability and versatility of HDPE pipes will undoubtedly make them a staple in infrastructure projects worldwide. It is clear that as we move forward, the role of these factories will only grow, shaping the future of how we build and maintain our urban environments.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025