Apr . 28, 2024 15:42 Back to list

Why are PPR Pipes reliable for use in plumbing?

Why are PPR Pipes reliable for use in plumbing?

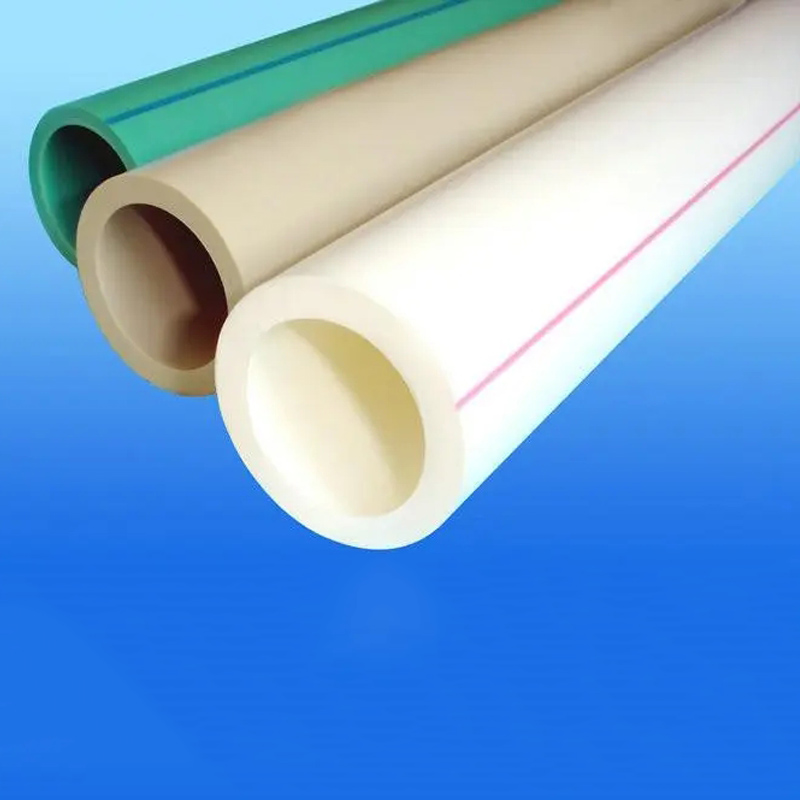

Compared with the traditional iron pipes, galvanized steel pipes, cement pipes and more, PPR pipes are energy-saving, environmentally friendly, and lightweight with high strength performance and outstanding corrosion resistance. Hence, it’s widely used in water supply in residential, municipal, industrial and agricultural fields.

Four types of PP materials you need to know

There are four types of PP materials, PP-H (Polypropylene Homopolymer), PP-B (Polypropylene Block Copolymer), PP-R (Polypropylene Random Copolymer) and PP-RCT (Polypropylene Random Crystalline-Structure Temperature). RIIFO mainly provides PP-R and PP-RCT Pipes. PP-H Pipe is easily brittle at low temperatures but has high temperature resistance. And PP-B Pipe has good impact resistance at low temperatures but poor high temperature resistance. Are there any pipes with good performance of great impact resistance at both low temperatures and high temperatures? The answer is yes. That is PP-R Pipe. PP-R is also called polypropylene random copolymer. The Pipe combines the advantages of PP-H Pipe and PP-B Pipe, so it is widely used in the cold and hot water supply. Currently, it's very popular in Asia, South America and other regions. The performance of PP-RCT is further improved based on that of PP-R. With innovative materials, PP-RCT has higher pressure resistance at high temperatures than PP-R.

-1656989237.jpg)

What are the advantages of the PPR Plumbing System?

The biggest advantage of the PPR Plumbing System is that it is affordable. It is more than 50% cheaper than multilayer pipes with the same specification. Second, PPR Pipes and Fittings are non-toxic and harmless to health. Moreover, with homogenized fusion as its way of connection, it is more reliable than the press connection of other pipes.

Seven types of RIIFO PPR Pipes are available

# RIIFO PPR Monolayer pipe

Compared with other pipes, the biggest advantage of PPR monolayer pipes is that they are affordable. Also, RIIFO PPR Monolayer Pipe obtained many international certifications like DVGW, NSF, AENOR, CE, EPD, etc.

# RIIFO PPR Double-layer Pipe

The double layers of this Pipe serve as an effective barrier to the permeation of light, effectively preventing the growth of bacteria and keeping the water clean and hygienic. What’s more, it features extraordinary chemical stability and excellent resistance to oxidation & corrosion.

# RIIFO Antibacterial Ceramic PP-R Pipe

Double and three layers are available for this Pipe, effectively preventing the permeation of light so that the water keeps clean and hygienic. The roughness of the inner surface is as low as 0.399um, yet that of an ordinary PPR pipe is up to 0.7 um. Hence, it’s smooth and non-scaling with a low resistance to water flow. In addition, Ag+ is added to the inner layer, which is highly antibacterial and more hygienic.

# RIIFO PP-R / Glass-Fiber Composite Pipe

RIIFO PP-R / Glass-Fiber Composite Pipe consists of PPR inner and outer layers and a special mixture of Glass Fiber (GF) & PPR as the middle layer. Its low linear expansion coefficient is about 0,05mm/mK. The pipes work at high temperatures for long without deformation. As for the Pipe with the three-layer structure design, this design makes the Pipe more stable and reliable, effectively preventing the permeation of light so that the water keeps clean and hygienic. And its excellent resistance to corrosion and extraordinary chemical stability can make its service lifespan last longer. Currently, RIIFO PP-R / Glass-Fiber Composite Pipe is certificated by famous international certifications like NSF.

# RIIFO PP-R / Basalt-fiber Composite Pipe

The most significant difference between Basalt-fiber Composite Pipe and Glass-Fiber Composite Pipe is that the middle layer is replaced by basalt and PPR, which is eco-friendly and 100% recyclable. Compared with ordinary PPR pipes, it features super high pressure resistance that is increased by 25%. Alike Glass-Fiber Composite Pipe, it has a low expansion coefficient, so it doesn't deform easily at high temperatures.

# RIIFO PP-RCT Pipe

PP-RCT, an innovative material, has higher pressure resistance than PPR at high temperatures.

It features a higher flow rate due to the thinner wall thickness. Its wall thickness of can be reduced by 15-28% more than PP-R pipes under the same working conditions. Therefore, it can save costs for users. Currently, RIIFO PP-RCT Pipe is Certificated by NSF.

DN25 PPR water pipes for kitchen

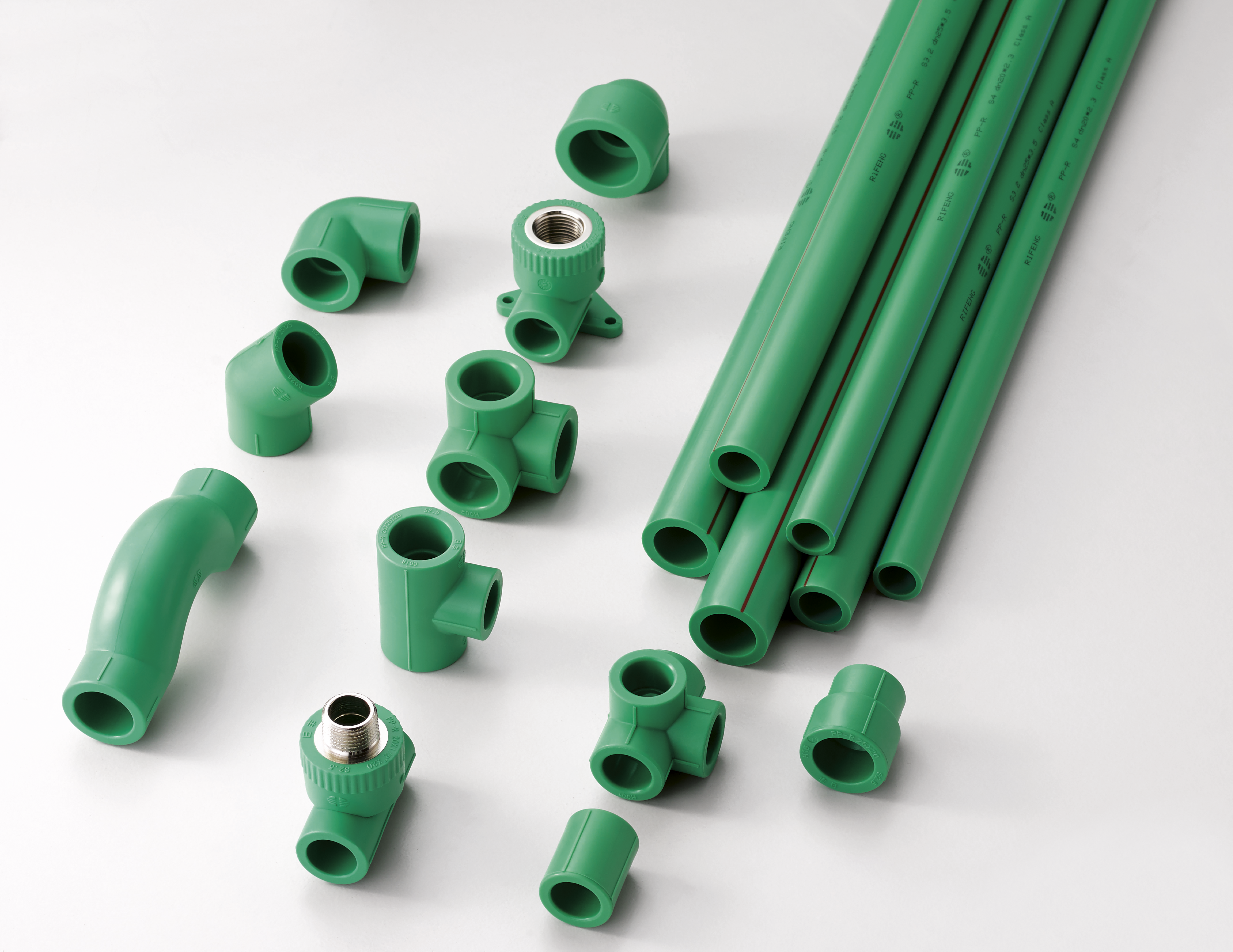

Four types of RIIFO PPR Fittings are available

1. RIIFO PP-R Large Flow Series

The large arc reduces the resistance to flow and the pressure loss.Two times heavier than ordinary PPR fittings.

The sweep junction with the reinforcement rib connects the main pipe and the branch pipe to enhance the overall stability of the pipe fittings.The sweep junction with the flow direction mark makes the installation easier and more convenient.

2. RIIFO PP-R Corner Tee/Side Outlet Tee

The unique multi-side design connects multiple directions, achieving a 90° turn in the pipeline.A better option for narrow areas such as wall corners.Fewer welded points cause lower risks of water leakage.Fewer pipes and fittings are needed for cost-effectiveness

3. RIIFO PP-R Inner Bridge Crossings

They are usually used for the interconnection of two pipelines to realize pipeline crossing.Easier installation and greater water flow. The flow rate can be increased by 77.8% compared with a bridge fitting.

Adjust the height more freely when installing.

4. RIIFO PP-R U-profile Tap Elbow

The Elbow will lead a circulation across all pipes in the house once the water flows out from the fixtures. Hence, it is more hygienic.The improved profile design greatly increases the flow rate.The hot water is accessible more quickly without waiting for the cold water in the pipeline to run out.

Installation ways of PPR pipes and fittings

There are four common installation types, including exposed installation, concealed installation, above-ground installation and underground installation. As far as we know, plastic has a characteristic. It expands when heating and shrinks when cooling. Therefore, pipes are easily deformed due to the ambient temperature, so we need to consider the expansion compensation of the pipes when installing. For example, we need to consider expansion compensation for surface installation to leave the space for expansion and contraction of pipes. However, concealed installation is not required to consider those factors because the cement will limit the expansion and contraction of the pipe. Hence, we do not need to consider expansion compensation in this part.

What is PP-R pipe installation tools?

To make the installation more convenient and provide a one-stop-shop service, RIIFO also provides tools for PP-R Piping Installation. For example, pipe cutters, heat fusion machines, heat fusion mold heads, flange adapter rings, flange adapters and much more are available.

Conclusion

PP-R Pipe Manufacturer

As one of the biggest PP-R Pipe Manufacture, RIIFO production capacity is up to 3.2 billion meters per year for pipes. With the excellent performance in application, RIIFO PP-R Pipes are proven to be reliable for every user.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025