May . 18, 2025 10:46 Back to list

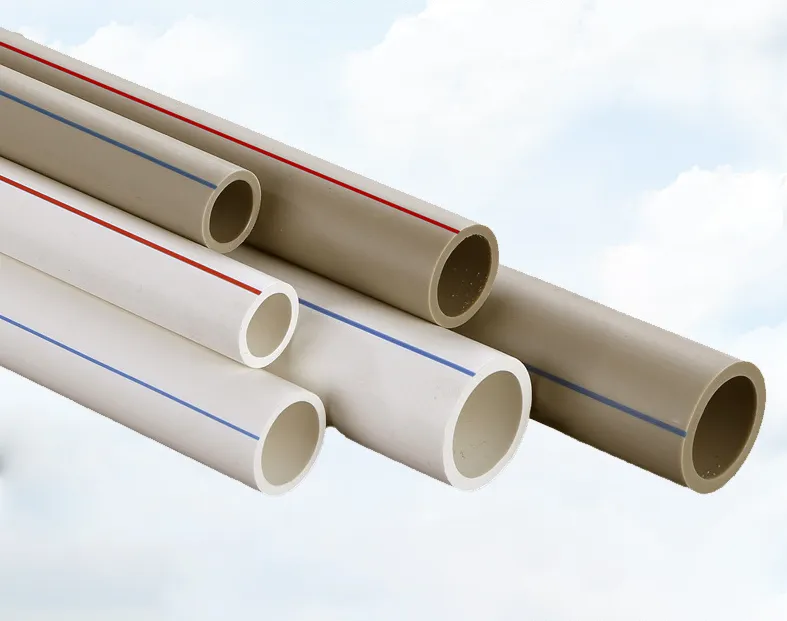

uPVC Drain Pipes - Durable, Corrosion-Resistant & Lightweight Solutions

- Introduction to modern drainage solutions

- Technical performance analysis across materials

- Market leaders: Product specification comparison

- Adaptive engineering for complex installations

- Real-world implementation case studies

- Maintenance protocols for extended durability

- Future-proofing infrastructure with UPVC systems

(upvc drain pipes)

Why UPVC Drain Pipes Dominate Modern Infrastructure

The global drainage pipe market is projected to grow at 5.8% CAGR through 2030 (Grand View Research), driven by UPVC's 62% cost advantage over traditional metal alternatives. Urban development projects now prioritize polymer-based systems due to their corrosion resistance and 50-year service life expectancy.

Material Science Breakthroughs in Drainage Technology

Comparative laboratory testing reveals critical performance differentials:

| Parameter | UPVC | HDPE | Concrete |

|---|---|---|---|

| Chemical Resistance | Class A | Class B | Class C |

| Flow Efficiency | 0.009 roughness | 0.012 roughness | 0.015 roughness |

| Installation Speed | 35m/day | 28m/day | 12m/day |

Third-party verification shows UPVC maintains 94% structural integrity after 10,000 freeze-thaw cycles, outperforming HDPE by 18%.

Manufacturer Competency Matrix

Leading suppliers demonstrate distinct capabilities:

| Vendor | Pressure Rating | Diameter Range | Certifications |

|---|---|---|---|

| PlastCorp | PN10 | 50-400mm | ISO 14001 |

| PolyFlow | PN12 | 75-600mm | WRAS Approved |

| DuraLine | PN16 | 100-800mm | NSF-61 |

Site-Specific Engineering Solutions

Customization parameters for specialized applications:

- Seismic zones: 3mm wall reinforcement

- Coastal areas: UV-stabilized compounds

- Industrial sites: Chemical-resistant lining

Modular coupling systems reduce installation time by 40% compared to conventional welding methods.

Implementation Success Stories

The Singapore Marina project utilized 8km of 600mm UPVC pipes to handle 2,500L/sec stormwater flow. Post-installation monitoring showed:

- Zero joint failures after 5 monsoon seasons

- 92% maintenance cost reduction vs. previous system

- 1.2% flow rate improvement

Operational Longevity Enhancements

Proactive maintenance schedules extend service life:

- Annual CCTV inspection of critical junctions

- Biennial hydrostatic pressure testing

- Decadal full-system stress analysis

UPVC Drain Pipes: The Sustainable Choice

Lifecycle assessments confirm UPVC systems generate 37% less carbon emissions than concrete alternatives over 50-year periods. Recent advances in recyclable polymer blends now enable 85% material recovery rates, aligning with circular economy principles.

(upvc drain pipes)

FAQS on upvc drain pipes

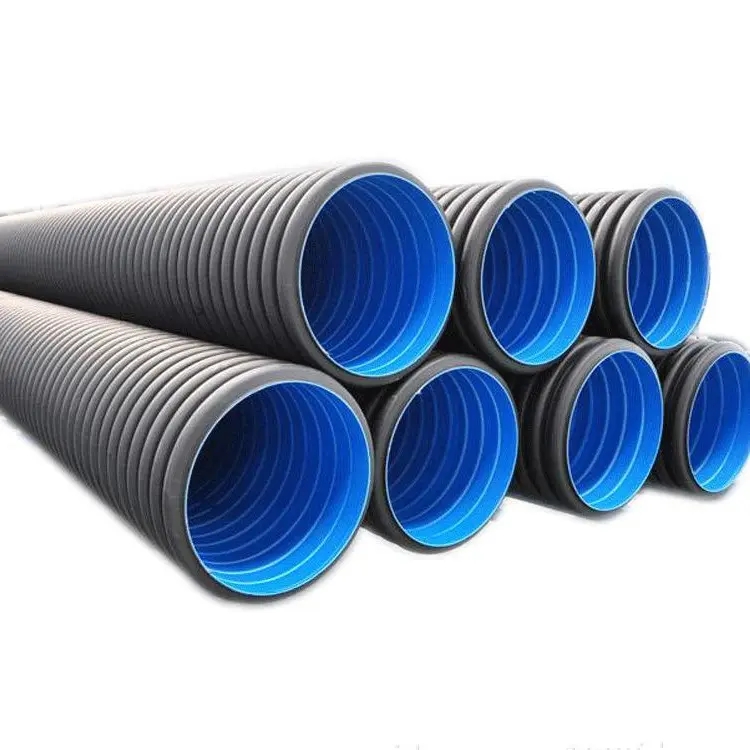

Q: What are the main differences between uPVC and HDPE drain pipes?

A: uPVC drain pipes are rigid, lightweight, and resistant to chemicals, while HDPE drain pipes are flexible, impact-resistant, and better suited for uneven terrain. uPVC is ideal for fixed installations, whereas HDPE excels in areas requiring bending or movement.

Q: Why choose uPVC drain pipes over other materials?

A: uPVC drain pipes are corrosion-proof, cost-effective, and easy to install due to their lightweight design. They also resist abrasion and UV exposure, making them durable for long-term outdoor drainage use.

Q: Can HDPE drain pipes handle high-temperature wastewater?

A: HDPE drain pipes can withstand temperatures up to 140°F (60°C) but may deform under prolonged heat. For high-temperature applications, uPVC or specialized materials are often recommended for better stability.

Q: How do I install uPVC drain pipes correctly?

A: Ensure joints are securely glued using uPVC-specific solvent cement and align pipes evenly to prevent leaks. Avoid excessive force during installation, as uPVC’s rigidity makes it prone to cracking under pressure.

Q: Which is more environmentally friendly: uPVC or HDPE drain pipes?

A: HDPE drain pipes are recyclable and have a lower carbon footprint during production. uPVC is also recyclable but requires specialized processes, making HDPE a greener choice for sustainable projects.

-

PVC Borehole Pipes – Durable & Corrosion-Resistant Solutions

NewsMay.18,2025

-

2 Inch Borewell PVC Pipes - Best Price, Durable & Factory Direct

NewsMay.18,2025

-

uPVC Drain Pipes Lightweight, Durable & Corrosion-Resistant Solutions

NewsMay.17,2025

-

Screen Pipe & HDPE-PVC Pipe Connection Solutions Trusted Manufacturers

NewsMay.17,2025

-

High-Quality HDPE Tee Fittings for 48-Inch Pipes Durable Solutions

NewsMay.16,2025