Oct . 08, 2024 09:43 Back to list

The Versatility and Durability of PVC Pipes: Unlocking Their Endless Applications

In the world of construction, plumbing, and irrigation, few materials have gained as much popularity and acclaim as PVC pipes. Short for Polyvinyl Chloride, PVC has revolutionized the way we handle water, sewage, and even gas transportation, thanks to its exceptional durability, cost-effectiveness, and ease of installation. From humble beginnings as a versatile plastic, pvc tubing have evolved into a staple in various industries, offering a wide range of PVC tubing options tailored to specific needs. Let's delve into the fascinating world of pvc tubing, exploring their types, sizes, and myriad uses.

What Are PVC Pipes?

PVC pipes are made from a synthetic polymer, polyvinyl chloride, which is a combination of vinyl chloride monomers. This material is renowned for its strength, resistance to corrosion, and lightweight nature, making it an ideal choice for a broad spectrum of applications. pvc tubing come in various forms, including rigid and flexible versions, each tailored to specific purposes.

PVC Pipe Types and Sizes

The versatility of PVC pipes lies in their diverse types and sizes, catering to the unique requirements of different industries. Here are some of the most common types and sizes you'll encounter:

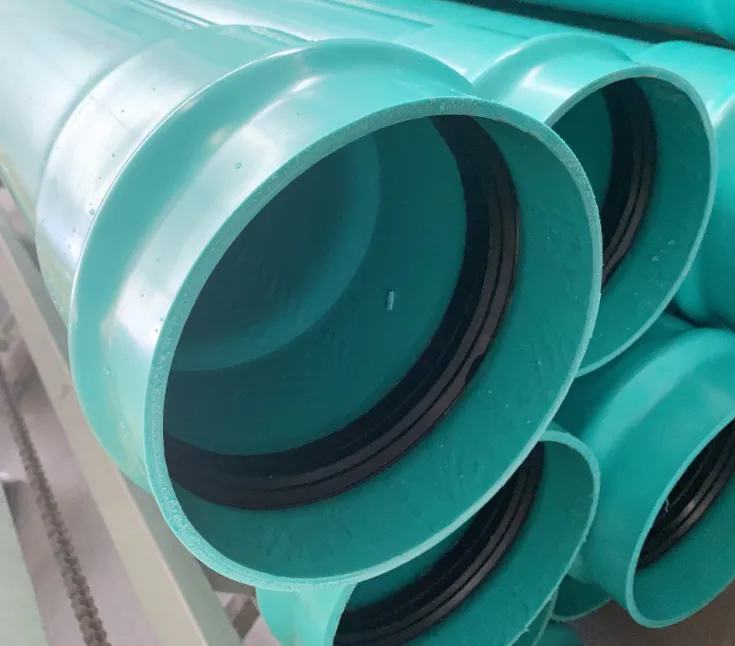

- PVC Sewer Pipe: Designed specifically for the transportation of sewage and wastewater, PVC sewer pipes are known for their resistance to corrosion and chemicals commonly found in sewage. They come in various diameters, with 110 mm PVC pipeand 160 mm PVC pipe being common sizes for residential and small-scale commercial applications.

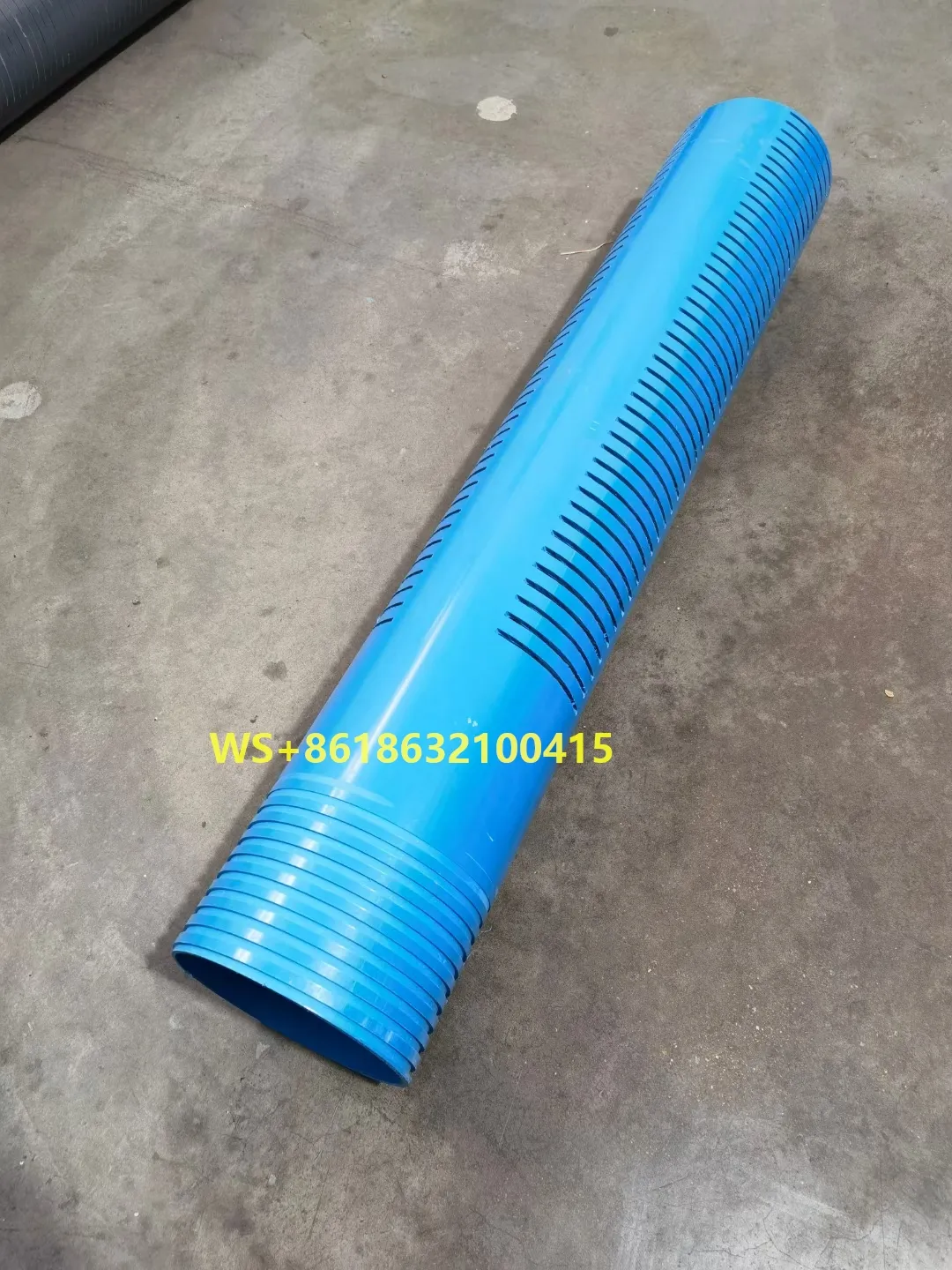

- PVC Irrigation Pipe: For agricultural purposes, PVC irrigation pipes are essential for efficient water distribution. These pipes, often referred to as sprinkler PVC pipeor drip irrigation tubing, come in a range of diameters, including 20mm PVC pipe for precision irrigation and larger diameters like 75mm plastic pipe for main lines. Their durability and resistance to UV radiation make them ideal for outdoor use.

- Rigid PVC Pipes: Commonly used in plumbing systems for water supply and drainage, rigid pvc tubing offer a combination of strength and flexibility during installation. Sizes range from small diameters like 20mm PVC pipefor domestic plumbing to larger diameters such as 90mm PVC pipe and 110 mm PVC pipe for commercial and industrial applications.

- Flexible PVC Tubing: Ideal for situations where flexibility is crucial, such as in ventilation systems or as hose lines. These pipes can be bent and shaped to fit tight spaces without compromising their structural integrity.

What Are PVC Pipes Used For?

The applications of pvc tubing are as vast as their types and sizes. Here are just a few of the many ways pvc tubing are utilized across various industries:

- Plumbing and Water Supply: pvc sewer pipe are a staple in modern plumbing systems, replacing traditional metal pipes due to their corrosion resistance and cost-effectiveness. They are used to transport clean water to homes and businesses, ensuring a safe and reliable water supply.

- Sewerage and Drainage: In sewage systems, PVC sewer pipes efficiently carry wastewater away from homes and businesses, minimizing the risk of leaks and corrosion. Their smooth interior walls also reduce the likelihood of clogs, ensuring smooth flow.

- Irrigation and Agriculture: The agricultural sector relies heavily on PVC irrigation pipes for efficient water distribution. From drip irrigation systems to large-scale sprinkler systems, PVC pipes ensure that crops receive the precise amount of water they need, promoting healthy growth and reducing water waste.

- Electrical Conduit: pvc tubing are also used as electrical conduits, protecting electrical wiring from damage and providing a safe, insulated path for electricity to flow.

- Ventilation and Ducting: In buildings, PVC pipes are often used for ventilation systems, carrying air to and from various rooms, ensuring proper air circulation and maintaining indoor air quality.

- Industrial Applications: From chemical processing to food and beverage manufacturing, PVC pipes are used in numerous industrial settings due to their chemical resistance and ability to withstand high pressures and temperatures.

Advantages of PVC Pipes

The widespread adoption of PVC pipes can be attributed to their numerous advantages, including:

- Durability: PVC pipes are highly resistant to corrosion, chemicals, and weathering, ensuring long-lasting performance.

- Cost-Effectiveness: Compared to traditional materials like metal or concrete, pvc tubing are more affordable, making them an economical choice for a wide range of projects.

- Ease of Installation: PVC pipes are lightweight and can be easily cut, joined, and installed, reducing labor costs and installation time.

- Maintenance-Free: Once installed, PVC pipes require minimal maintenance, saving time and money in the long run.

- Environmentally Friendly: PVC is a recyclable material, and many manufacturers offer recycled PVC pipes, reducing waste and promoting sustainability.

In conclusion, PVC pipes are a testament to the power of innovation and material science. Their versatility, durability, and cost-effectiveness have made them indispensable in various industries, from plumbing and irrigation to electrical and industrial applications. As we continue to explore new ways to improve our infrastructure and resource management, pvc tubing will undoubtedly play a pivotal role in shaping a more sustainable and efficient future. Whether you're a homeowner looking to upgrade your plumbing system or a business owner seeking efficient irrigation solutions, PVC pipes offer a reliable and cost-effective option that's sure to meet your needs.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025