Oct . 09, 2024 13:45 Back to list

The Versatility and Durability of PPR Pipes: Revolutionizing Plumbing Systems

In the world of modern plumbing, advancements in materials have played a pivotal role in enhancing the efficiency, durability, and safety of water distribution systems. Among these innovative materials, PPR pipes (Polypropylene Random Copolymer pipes) have emerged as a game-changer, offering a combination of superior qualities that make them an ideal choice for a wide range of residential, commercial, and industrial applications. In this comprehensive blog, we delve into the intricacies of ppr plumbing, exploring their types, benefits, usage, and how they stack up against traditional materials like PVC pipes.

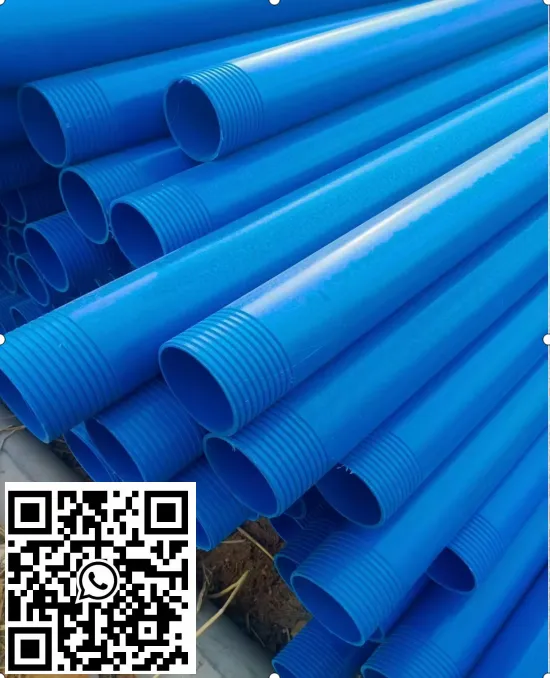

PPR pipes are a type of thermoplastic piping system that utilizes polypropylene, a versatile polymer with excellent resistance to chemical corrosion, high temperatures, and pressure. These pipes are renowned for their high flexibility, durability, and ease of installation, making them a popular choice in ppr plumbing systems worldwide. The random copolymerization process during manufacturing imparts unique properties to PPR, enhancing its overall performance in various environments.

Types of PPR Pipe

When it comes to ppr tube, there are several types available in the market, each designed to cater to specific needs and applications. Some of the most common types include:

- PPR Tube: The most basic form, PPR tubes are available in various diameters, ranging from small-scale domestic use to larger-diameter pipes for industrial applications.

- PPR CT Pipe(Cold Temperature Resistant): Specially designed for cold environments, these pipes exhibit enhanced resistance to low temperatures, ensuring reliable performance even in freezing conditions.

- Diameter Variations: Common diameters include 20mm PPR pipe, 25mm PPR pipe, and PPR pipe 32mm, among others, offering flexibility in design and installation for various plumbing layouts.

Benefits of PPR Pipes

PPR pipes offer a myriad of advantages that make them stand out from other piping materials:

- High Durability: ppr tubeare known for their long lifespan, withstanding even harsh conditions and maintaining structural integrity over time. Their resistance to corrosion, scaling, and chemical attack ensures that water quality remains unaffected.

- Temperature Resistance: These pipes can withstand a broad range of temperatures, from low to high, making them suitable for both hot and cold water distribution systems. This feature is particularly useful in heating systems, where PPR pipescan endure the heat without deforming or losing their properties.

- Easy Installation and Maintenance: PPR pipesare lightweight and flexible, facilitating quick and efficient installation processes. Additionally, their smooth interior surfaces reduce the risk of clogging and make maintenance tasks easier.

- Environmentally Friendly: PPR pipesare recyclable and do not leach harmful chemicals into the water, making them an eco-friendly choice for modern plumbing systems.

- Cost-Effective: While the initial investment in PPR pipesmay be slightly higher than some traditional materials, their longevity and low maintenance costs often translate into significant cost savings over the long term.

PPR Plumbing Fittings

The effectiveness of any piping system heavily relies on the quality of its fittings. PPR plumbing fittings, including elbows, tees, couplings, and valves, are designed to seamlessly integrate with PPR pipes, ensuring a leak-proof and durable connection. These fittings are typically made from the same material as the pipes, ensuring compatibility and maintaining the overall performance of the system.

PPR Pipe Heating Time

When installing PPR pipes, one of the key steps involves the use of heat to fuse the pipes and fittings together, creating a permanent, leak-proof joint. The heating time required for this process varies depending on the specific PPR grade, pipe diameter, and ambient conditions. Generally, a specialized tool known as a butt fusion welder is used to heat the ends of the pipe and fitting to a precise temperature, followed by a swift and precise connection. Proper heating and cooling cycles are crucial to ensure a strong and reliable joint.

PPR Pipe vs PVC Pipe

PPR pipes are often compared to PVC (Polyvinyl Chloride) pipes, another popular choice in plumbing systems. While both materials have their strengths, PPR pipes offer several advantages:

- Temperature Resistance: While PVC pipes are suitable for cold water applications, PPR pipesexcel in both hot and cold water systems, withstanding higher temperatures without degradation.

- Chemical Resistance: ppr plumbingexhibit superior resistance to chemicals, including acids and alkalis, making them ideal for use in environments where water quality is critical.

- Durability and Longevity: PPR pipestend to have a longer lifespan than PVC pipes, thanks to their resistance to corrosion and scaling.

- Installation Flexibility: ppr plumbingare more flexible than PVC pipes, making them easier to install in tight spaces and around obstacles.

However, it's important to note that PVC pipes remain a cost-effective option for many applications, particularly those that do not require high temperature resistance or exceptional chemical resistance.

In conclusion, PPR pipes have revolutionized the plumbing industry with their unique combination of durability, flexibility, and ease of installation. Their ability to withstand a wide range of temperatures and chemicals, along with their eco-friendly nature, make them an ideal choice for modern plumbing systems. Whether you're designing a new residential plumbing layout or upgrading an industrial water distribution network, ppr plumbing offer a reliable and cost-effective solution that can stand the test of time. As the demand for sustainable and efficient plumbing solutions continues to grow, PPR pipes are poised to play an even more significant role in shaping the future of water distribution.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025