Dec . 18, 2024 11:36 Back to list

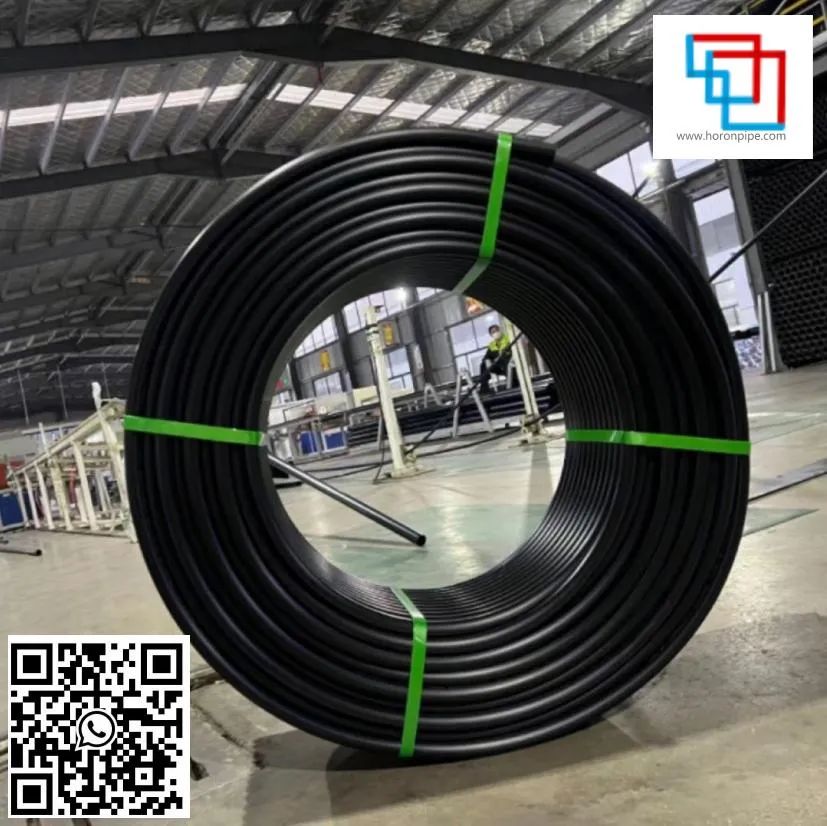

The Use Of Hdpe Irrigation Pipe Fittings In Industry

HDPE irrigation pipe fittings have been widely used in the industrial field due to their excellent physical and chemical properties. HDPE has excellent corrosion resistance, superior toughness, and low water friction coefficient, making it an ideal material for water supply pipelines. China 25mm HDPE pipes, The application of HDPE water supply pipes will effectively improve the efficiency and safety of industrial water systems, from water treatment, mining to agricultural irrigation.

The corrosion resistance of HDPE irrigation pipe fittings enables them to be used in various harsh environments

Compared with traditional metal pipes, HDPE water supply pipes are less susceptible to corrosion by chemicals such as acids and alkalis, which has made them widely used in industries such as chemical plants, mining, and sewage treatment plants. In these industries, pipelines often need to withstand high concentrations of chemicals, but HDPE pipelines can effectively prevent leakage and damage caused by corrosion, thereby improving the safety and reliability of industrial production.

The toughness and strength of HDPE rigidity pipe fittings make them more convenient for transportation and installation

The lightweight nature of HDPE water service pipes reduces the complexity of handling and installation, thereby saving labor and time costs. In addition, HDPE material has good bending performance and can be flexibly arranged in limited spaces to meet the requirements of complex pipe network structures. This is particularly important in certain industrial settings, such as urban water supply systems and large industrial parks, where flexible pipeline layout can effectively improve water use efficiency. China 25mm HDPE pipes.

The low water friction coefficient of HDPE irrigation pipe fittings can significantly reduce water flow resistance, improve water delivery efficiency, and reduce energy consumption

In some industrial applications that require long-distance water transportation, using water supply HDPE pipes will help reduce overall energy consumption and achieve environmental protection goals. In addition, the smooth inner wall of HDPE pipes effectively reduces the accumulation of dirt and sediment, keeping water quality cleaner and meeting the higher requirements of modern industry for water quality.

The lifespan of hdpe pipe for potable water is extremely long, china 25mm HDPE pipes, typically exceeding 50 years, and they require almost no maintenance during use. This durability will effectively reduce the operating costs of enterprises, especially in industries that require frequent pipeline replacement. The application of HDPE is undoubtedly a more cost-effective choice.

In summary, high-density polyethylene water supply pipes have become an important water supply material in the industrial field due to their corrosion resistance, toughness, low friction coefficient, and long-term economic viability. With the continuous advancement of industrial technology and the increasing awareness of environmental protection, the application prospects of HDPE water supply pipes will be even broader and worthy of further promotion and research.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025