Nov . 22, 2024 16:29 Back to list

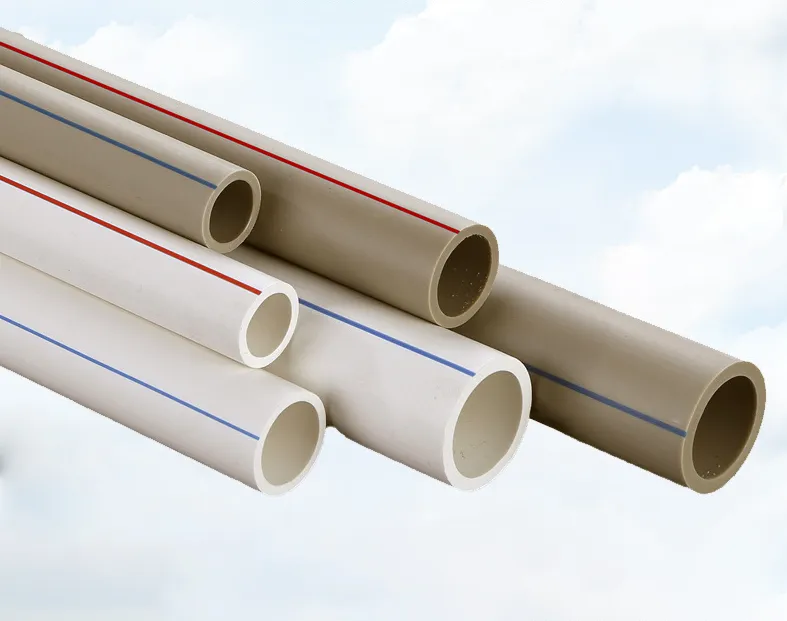

Reliable PPR Pipe Factories

PPR pipes have become a popular choice for plumbing, water supply systems, and heating applications due to their high durability, corrosion resistance, and safe, non-toxic material. They are particularly favored in both residential and commercial plumbing systems, as well as for industrial uses. In this guide, we will explore the types of PPR pipes, how to choose a reliable PPR pipe factory, and what factors affect PPR pipe prices.

Why Choose PPR Pipes?

Polypropylene Random Copolymer, commonly known as PPR, is a type of thermoplastic material known for its excellent resistance to heat, pressure, and chemical reactions. Here are some advantages of using PPR pipes:

- Corrosion Resistance: PPR pipes are highly resistant to corrosion and scaling, ensuring long-lasting performance.

- Durability and Flexibility: With a lifespan of over 50 years, these pipes are ideal for high-temperature and high-pressure applications.

- Non-Toxic and Safe for Drinking Water: PPR is safe for potable water, as it does not release harmful chemicals.

- Heat Resistance: Capable of withstanding temperatures up to 95°C (203°F), making it suitable for hot and cold water applications.

- Easy Installation: These pipes are lightweight, making transport and installation relatively easy.

Different Types of PPR Pipes

PPR pipes come in several types based on their application, thickness, and pressure handling capabilities. Understanding these types can help you select the right one for your project:

PPR Cold Water Pipes:

- Application: These pipes are designed specifically for cold water applications, with a maximum temperature limit of around 20°C (68°F).

- Common Uses: Water distribution in residential and commercial buildings.

- Key Feature: Affordable and designed to handle standard water pressures.

PPR Hot Water Pipes:

- Application: Made to withstand higher temperatures, often up to 95°C (203°F), making them suitable for hot water systems.

- Common Uses: Domestic hot water systems, heating systems, and industrial applications where high temperatures are involved.

- Key Feature: Greater resistance to heat and pressure, ensuring safe water supply for hot water systems.

PPR Composite Pipes:

- Application: These pipes have layers of PPR combined with materials like aluminum or fiberglass to improve durability and strength.

- Common Uses: Heating systems, pressurized systems, and industrial applications requiring higher performance.

- Key Feature: Enhanced strength and resistance to temperature fluctuations, making them a preferred choice for industrial uses.

PPR UV-Resistant Pipes:

- Application: UV-resistant pipes are manufactured with a special coating to protect them from degradation due to sunlight exposure.

- Common Uses: Outdoor installations or exposed piping systems.

- Key Feature: Extended lifespan and protection from UV rays, ensuring durability even under direct sunlight.

PPR Antibacterial Pipes:

- Application: Infused with antibacterial agents, these pipes are used in applications where hygiene is critical.

- Common Uses: Hospitals, laboratories, food and beverage industries, and areas requiring stringent hygiene standards.

- Key Feature: Prevents bacterial growth within the pipe system, ensuring a safer water supply.

PPR Fiber-Reinforced Pipes:

- Application: Fiber-reinforced pipes include a layer of fiber to enhance durability, reduce thermal expansion, and improve performance under pressure.

- Common Uses: Heating systems, hot water plumbing, and high-pressure applications.

- Key Feature: Reduced thermal expansion, which minimizes pipe movement and prolongs system integrity.

Selecting a Reliable PPR Pipe Factory

Choosing a trusted PPR pipe factory is crucial for getting high-quality pipes that meet the necessary standards. Here are factors to consider when selecting a factory:

Quality Certifications:

- Reliable PPR pipe factories adhere to international quality standards like ISO, ASTM, and DIN certifications. These certifications ensure the pipes are manufactured with quality and durability in mind.

Product Range:

- A reputable factory offers a variety of PPR pipes, including different types, sizes, and pressure ratings. This enables customers to find products that match their specific requirements.

Manufacturing Process and Technology:

- Modern factories use advanced technology and machinery to manufacture pipes. A high-tech production process generally results in better precision, durability, and consistency.

Raw Material Quality:

- High-grade PPR raw materials play a significant role in the quality of the final product. Look for factories that source premium materials and can verify the origin and quality of their supplies.

Customer Support:

- Reliable factories provide excellent customer support, including expert guidance on product selection, after-sales service, and technical assistance if needed.

Reputation and Reviews:

- Checking reviews, testimonials, and the factory’s reputation in the market can offer insights into the quality and reliability of their products. A factory with positive feedback is often a safer choice.

Competitive Pricing and Shipping:

- Pricing should be competitive, but it’s essential to balance cost with quality. Additionally, some factories offer bulk discounts or flexible shipping options, making it easier for larger orders.

Understanding PPR Pipe Prices

PPR pipe prices can vary based on factors such as size, type, and the quality of raw materials. Here’s what influences pricing:

Pipe Type:

- Hot water pipes, UV-resistant pipes, and fiber-reinforced pipes generally cost more than standard cold water pipes due to their enhanced properties and durability.

Pipe Diameter and Thickness:

- Larger diameters and thicker walls require more material, leading to higher prices. When choosing pipes, ensure you select the appropriate size to avoid overspending.

Raw Material Costs:

- The cost of raw materials directly impacts the price. Factories that use premium PPR resins may have slightly higher prices, but the quality is generally better.

Quantity and Order Size:

- Ordering in bulk often results in discounts, as many factories provide price breaks for larger quantities. If your project requires extensive piping, buying in bulk can help reduce costs.

Market Demand and Location:

- Local demand and transportation costs influence the final price of PPR pipes. In areas with high demand, prices may be slightly elevated, while rural locations may incur additional transportation costs.

Brand Reputation:

- Established brands with a reputation for high-quality PPR pipes may charge a premium. However, opting for a reputable brand often guarantees better product quality and service.

When considering PPR pipes for your next project, understanding the various types of PPR pipes and how to choose a reliable PPR pipe factory is essential to make an informed purchase. While PPR pipe prices vary depending on size, type, and quality, investing in high-quality pipes will pay off in the long run by ensuring durability and system integrity.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025