HDPE and PVC pipe have several similarities, but there are important differences that you should understand when choosing a product. At Piedmont Plastics, we want you to have the right plastic for your specific application, and that’s why we want to point out these differences.

Both PVC and HDPE are durable and lightweight options for piping in residential and commercial buildings. They carry a low risk of leaks, can carry gas and liquid, and can be used underground and in the water. Both are corrosion-proof and resistant to bacteria and chemical buildup as well. Yet, despite these similarities, distinct differences can dictate which choice is best for your needs.

Differences Between PVC & HDPE

PVC and HDPE have some distinct differences. In general, HDPE is a flexible, strong, and impermeable plastic. PVC is also strong but less flexible and more prone to cracking and failure.

Both pipes can handle standard water pressure surges common in pipelines. However, with PVC, the pipe can handle 100 psi above its pressure class. With HDPE, the pipe can withstand twice the pressure class. In addition, PVC can handle 5.5 feet per second of flow rate before changing its water pressure rating, while HDPE can handle 14 feet per second. Overall, HDPE is 2,500 more resistant to cracking and failure due to water hammer and fatigue.

PVC has a higher pressure class for static water, but HDPE has a higher working pressure rating. In addition, when creating pipe systems, HDPE has a greater bend radius, so it works well for applications that require a curved or bent design.

These two materials also vary in how they are joined. For example, HDPE is joined with heat fusion, while PFC must have a spigot or bell joint with cement. This means HDPE has less of a risk of leaks at the joints.

Finally, HDPE is more durable under extreme conditions. Unlike PVC, it is completely UV resistant and can be installed in extreme temperatures ranging from -40 to 140 degrees. It also has a service life of over a century.

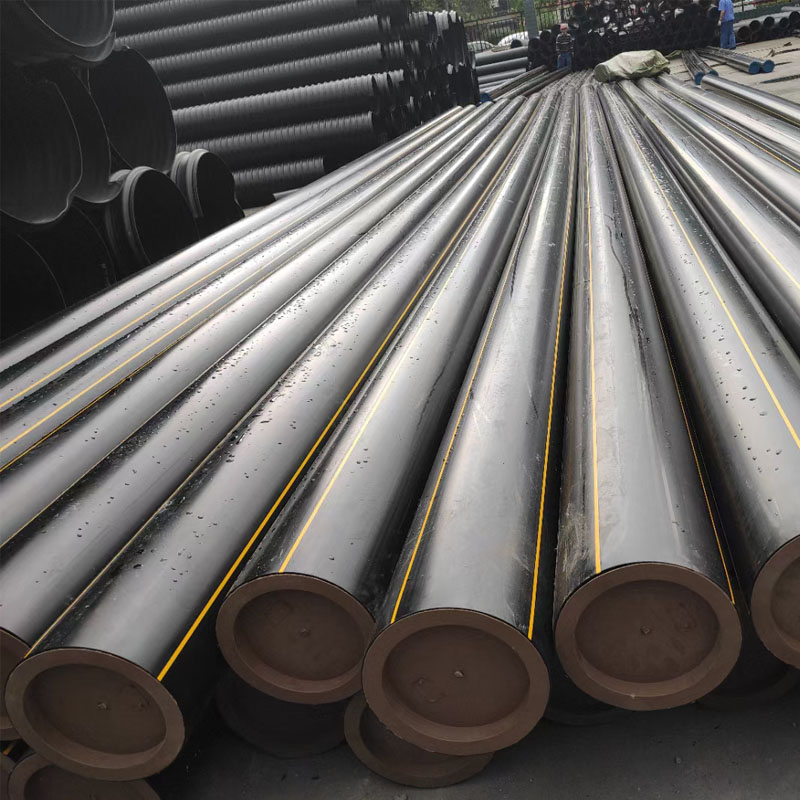

DN50 HDPE pipes in coils

Different Applications of PVC & HDPE Pipe

While the most common use of HDPE and PVC pipe is plumbing, these products have additional applications:

Common HDPE Applications

-

Water and gas mains

-

Sewage

-

Irrigation

-

Slurry transfers

-

Stormwater and drainage

-

Electrical and communications conduits

-

Mining applications

-

Firewater

-

Brine lines

-

Process chemicals

-

Ocean clean-up

-

Outtfall lines

Common PVC Applications

-

Water mains

-

Chemical transfers

-

Stormwater drainage

-

Sewage

-

Household plumbing

-

Irrigation

-

Underwater Piping

-

Exhust fumes

Chemical Resistance and Compatability

HDPE and PVC differ in their resistance to certain chemicals. They have the same chemical resistance for the following:

Acetic acid, Ammonium Sulfate, Ammonium Hydroxide, Borax, Calcium hypochlorite, Ferrous sulfate, Hydrochloric acid, Hypochlorous acid, Phosphoric acid, Sodium bicarbonate, Sodium carbonate, Sodium chloride, Sulfur, Urine, Water, and Saltwater.

Some chemicals had distinct differences. These include:

-

Chlorine at 50+ ppm: PVC is more resistant

-

Nitric acid: HDPE is more resistant

-

Lubricating oil: HDPE is more resistant

-

Sodium HypoChlorite: PVC is more resistant

-

Sulfuric Acid: HDPE is more resistant at most concentrations

Which Is More Cost -Effective: HDPE or PVC?

Even though HDPE is more durable and flexible than PVC and lasts longer without degradation, it costs a little more than its competition. However, when considering cost-effectiveness, you must look beyond the purchase price.

With HDPE, you don’t have to use cement to join pieces. Because it is joined with heat, the process requires minimal wait time. As a result, you do not have to wait for the cement to cure, and you can use your new pipes more quickly.

HDPE is also more cost-effective to transport. You do not have to protect it from sunlight as you do with PVC because it is UV resistant. This combination of less cost and time to install and less cost for transportation helps counter the higher purchase cost.

Finally, HDPE will last longer than PVC in most applications. Not having to replace and repair pipes as often adds up to major cost savings. In light of these factors, HDPE is typically the more cost-effective option.