Jul . 23, 2024 14:35 Back to list

High Quality HDPE Pipe Couplers Manufacturers and Suppliers for Durable Plumbing Solutions

The Role of Coupler HDPE Pipe Factories in Modern Infrastructure

High-Density Polyethylene (HDPE) pipes have become a staple in various industries due to their flexibility, durability, and resistance to a multitude of environmental factors. Coupler HDPE pipe factories play a crucial role in the production of these pipelines, particularly in providing a reliable method for connecting segments of HDPE pipes, thereby ensuring the integrity and efficiency of infrastructure projects.

Understanding HDPE Pipes

HDPE pipes are known for their high strength-to-density ratio, which makes them an excellent choice for a wide range of applications, including water supply, sewage systems, and gas distribution. Unlike traditional materials such as PVC or metal, HDPE pipes are less prone to corrosion, which extends their lifespan and reduces maintenance costs. Their lightweight nature simplifies transportation and installation, making them a preferred choice for contractors and engineers alike.

Importance of Couplers

The couplers produced in HDPE pipe factories are essential fittings that join two individual pipe lengths securely. Given the nature of pipeline installation, which often involves varying lengths and configurations, couplers provide the necessary adaptability to create a seamless pipeline system. These couplings not only ensure tight connections that prevent leaks but also accommodate the thermal expansion and contraction of HDPE material, thus enhancing overall pipeline performance.

The Manufacturing Process

Manufacturing HDPE couplers is a meticulous process aimed at ensuring reliability and quality. Factories utilize advanced extrusion technology to create couplers that meet precise dimensional specifications. The process typically begins with the selection of high-quality polymers, which are then melted and formed into the desired shapes using sophisticated machinery. Rigorous quality control checks are conducted throughout the production process to ensure that each coupler meets industry standards and client specifications.

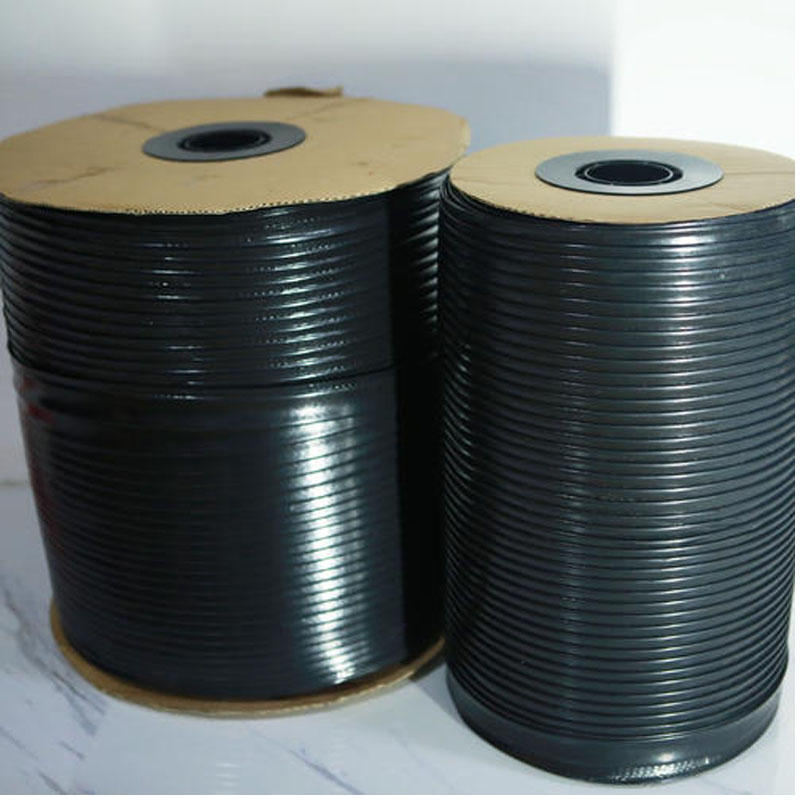

coupler hdpe pipe factories

Additionally, many HDPE pipe factories are now focusing on sustainability in their manufacturing processes. They are adopting eco-friendly practices such as recycling waste materials and utilizing energy-efficient technologies, helping to reduce the carbon footprint associated with production. This emphasis on sustainability not only aids in compliance with environmental regulations but also appeals to increasingly eco-conscious consumers.

Innovations and Technology

As the demand for efficient infrastructure solutions grows worldwide, so does the need for innovation in coupler design and technology. Modern couplers come equipped with various features such as built-in seals for enhanced leak prevention and designs that enable quick installation without the need for specialized tools. Furthermore, many manufacturers are investing in research and development to create couplers that can handle higher pressures and harsher environmental conditions, catering to a broader range of applications.

Market Trends and Future Prospects

The global market for HDPE pipes and couplers is projected to grow significantly in the coming years. Driven by investments in infrastructure development, urbanization, and a shift towards sustainable materials, there is an increasing demand for durable and efficient piping solutions. Coupler HDPE pipe factories are strategically positioned to meet this demand by expanding their product lines, enhancing production capabilities, and exploring new markets.

Moreover, with the ongoing advancements in smart technology, there is potential for integrating IoT capabilities into pipe systems, allowing for real-time monitoring and maintenance. This prospect further emphasizes the critical role of couplers as integral components of intelligent infrastructure.

Conclusion

In conclusion, Coupler HDPE pipe factories are pivotal in the production of high-quality, reliable piping systems that are essential to modern infrastructure. By ensuring secure connections and innovating to meet contemporary demands, these factories contribute significantly to the efficiency and sustainability of utility networks, construction projects, and various industrial applications. As technology continues to evolve, the future looks promising for both HDPE pipes and the factories that manufacture them, highlighting an exciting path forward for infrastructure development worldwide.

-

HDPE Compression Fittings Durable & Reliable PP Compression Fittings Supplier

NewsJun.24,2025

-

High-Quality PVC Borehole Pipes - Durable Pipes from Leading PVC Manufacturer

NewsJun.10,2025

-

High-Quality PVC Borehole Pipes Types of Pipes by Leading PVC Manufacturer

NewsJun.10,2025

-

Durable Screen Pipes & HDPE-PVC Connectors Expert Solutions

NewsJun.10,2025

-

Premium HDPE Conduit Pipes Durable & Corrosion-Resistant

NewsJun.10,2025

-

Premium HDPE Elbows Durable Corrosion-Resistant Piping Solutions

NewsJun.09,2025