Jun . 12, 2024 19:56 Back to list

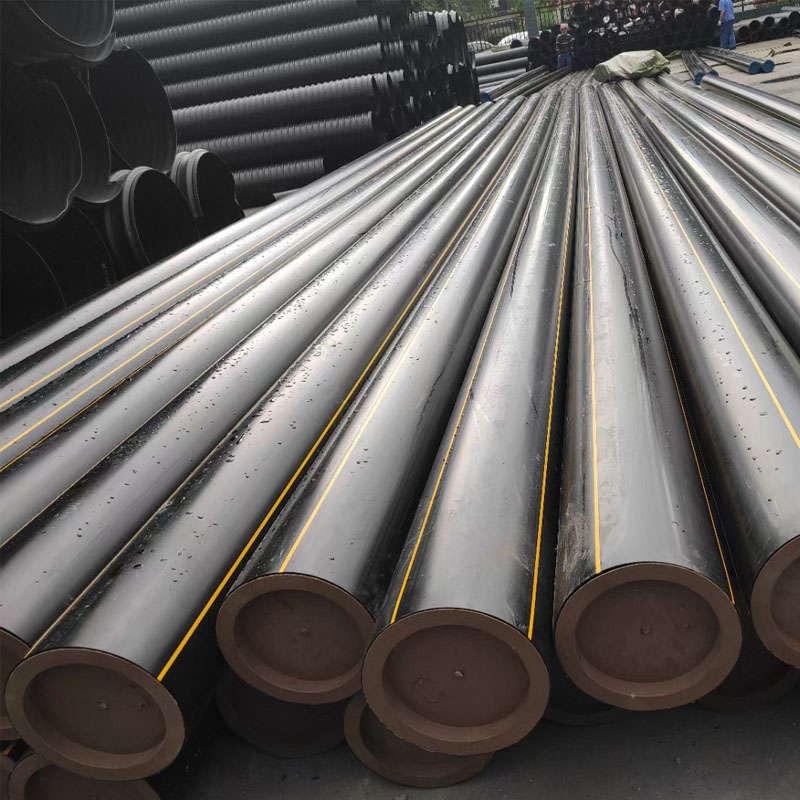

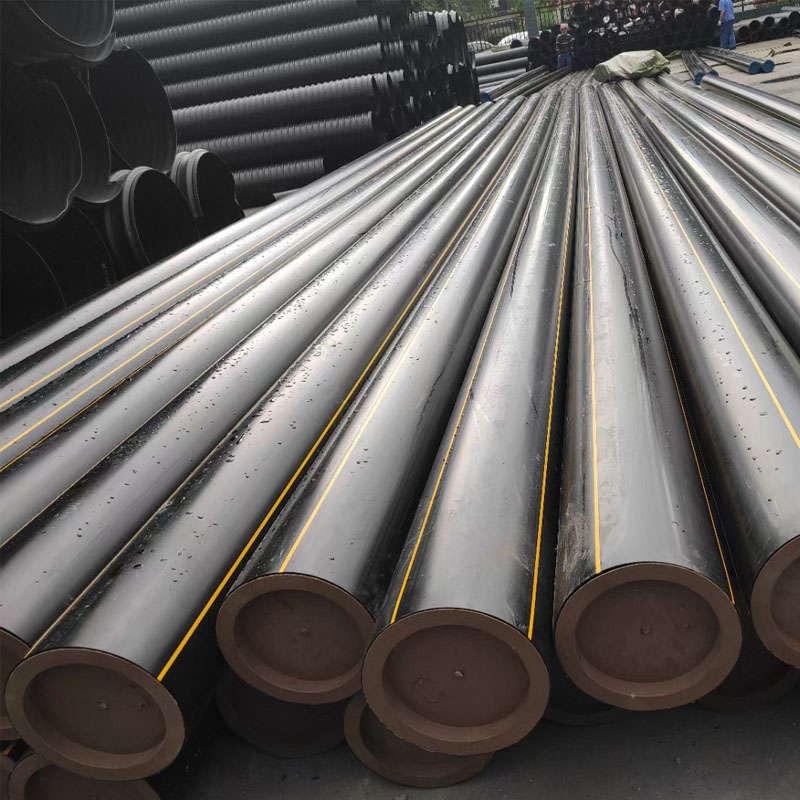

Here are ten short phrases with around ten words each related to HDPE sprinkler pipe factories 1. HDPE spray pipes production. 2. Manufacture of HDPE irrigation pipes. 3. HDPE sprinkler pipe factory.

For instance, researchers are exploring the use of additives to enhance the barrier properties of HDPE pipes, making them more resistant to water penetration For instance, researchers are exploring the use of additives to enhance the barrier properties of HDPE pipes, making them more resistant to water penetration

For instance, researchers are exploring the use of additives to enhance the barrier properties of HDPE pipes, making them more resistant to water penetration For instance, researchers are exploring the use of additives to enhance the barrier properties of HDPE pipes, making them more resistant to water penetration hdpe sprinkler pipe factories. Additionally, new coupling and fitting technologies have been developed to improve the reliability and ease of installation and maintenance of HDPE sprinkler systems.

The environmental impact of HDPE sprinkler pipe manufacturing has also been a focus of attention. Many manufacturers are now adopting eco-friendly practices such as recycling scrap material, optimizing energy consumption, and using renewable energy sources in their production processes. The adoption of these practices not only helps reduce the environmental footprint of HDPE sprinkler pipes but also provides an opportunity for companies to differentiate themselves in the market.

Overall, the advancements in HDPE sprinkler pipe manufacturing have led to significant improvements in terms of quality, efficiency, and sustainability. As the demand for water supply and irrigation systems continues to grow, it is expected that these trends will continue and drive further innovation in this sector.

hdpe sprinkler pipe factories. Additionally, new coupling and fitting technologies have been developed to improve the reliability and ease of installation and maintenance of HDPE sprinkler systems.

The environmental impact of HDPE sprinkler pipe manufacturing has also been a focus of attention. Many manufacturers are now adopting eco-friendly practices such as recycling scrap material, optimizing energy consumption, and using renewable energy sources in their production processes. The adoption of these practices not only helps reduce the environmental footprint of HDPE sprinkler pipes but also provides an opportunity for companies to differentiate themselves in the market.

Overall, the advancements in HDPE sprinkler pipe manufacturing have led to significant improvements in terms of quality, efficiency, and sustainability. As the demand for water supply and irrigation systems continues to grow, it is expected that these trends will continue and drive further innovation in this sector. -

HDPE Compression Fittings Durable & Reliable PP Compression Fittings Supplier

NewsJun.24,2025

-

High-Quality PVC Borehole Pipes - Durable Pipes from Leading PVC Manufacturer

NewsJun.10,2025

-

High-Quality PVC Borehole Pipes Types of Pipes by Leading PVC Manufacturer

NewsJun.10,2025

-

Durable Screen Pipes & HDPE-PVC Connectors Expert Solutions

NewsJun.10,2025

-

Premium HDPE Conduit Pipes Durable & Corrosion-Resistant

NewsJun.10,2025

-

Premium HDPE Elbows Durable Corrosion-Resistant Piping Solutions

NewsJun.09,2025