Dec . 10, 2024 00:35 Back to list

HDPE Conduit Fittings Manufacturing Process and Quality Standards Overview

HDPE Conduit Fittings Factory An Overview of Production and Innovation

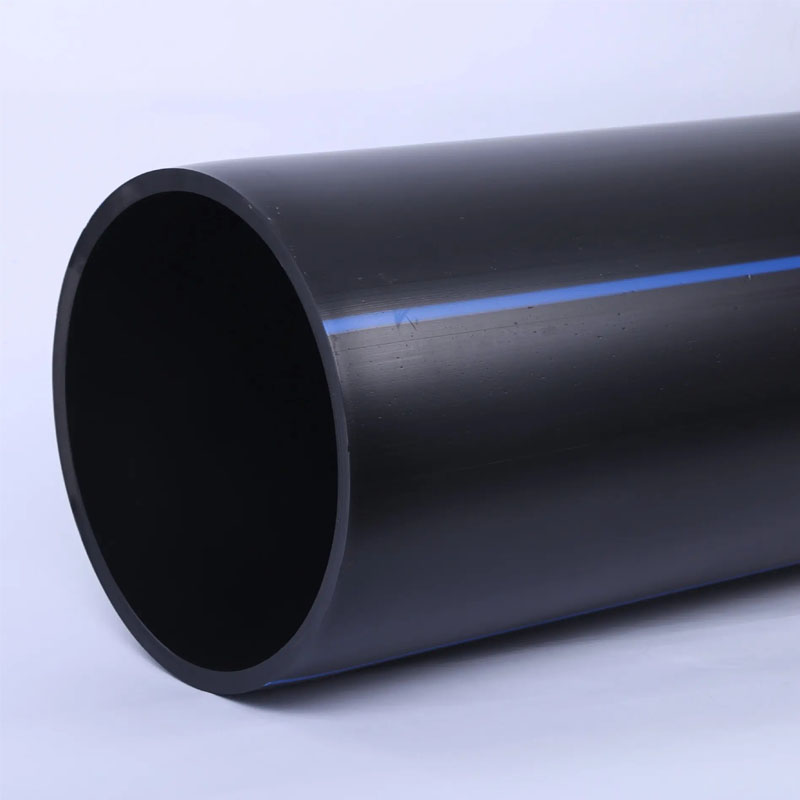

High-Density Polyethylene (HDPE) has become a staple material in the manufacturing of various fittings and conduits due to its durability, flexibility, and resistance to chemical corrosion. A factory specializing in HDPE conduit fittings typically focuses on producing a range of components that are integral to electrical and telecommunications installations. This article will delve into the processes, advantages, and innovations associated with HDPE conduit fittings manufacturing.

Understanding HDPE and Its Significance

HDPE is a type of thermoplastic polymer made from petroleum, characterized by its high strength-to-density ratio. It is widely used in both industrial and commercial applications due to its versatility. Among its many uses, HDPE is particularly favored in the production of conduits and fittings due to the material's resistance to impact, UV radiation, and moisture. These properties ensure that HDPE conduits and fittings maintain their integrity even in harsh environments, making them ideal for underground and above-ground installations.

The Manufacturing Process

The manufacturing process of HDPE conduit fittings typically involves several steps

1. Material Extrusion The journey begins with the extrusion of HDPE pellets, which are heated until they become molten. This molten plastic is then forced through a die to produce conduits or fittings of desired shapes and sizes. The ability to control temperature and pressure during this process allows manufacturers to ensure a consistent quality in the final products.

2. Molding Fittings are often produced using various molding techniques, including injection molding and blow molding. Injection molding is commonly used for creating complex shapes with high precision. The process involves injecting molten HDPE into a mold and allowing it to cool and solidify, resulting in the required components.

3. Quality Control After production, a rigorous quality control process is essential. Each fitting must meet safety standards and specifications, including pressure ratings and resistance to environmental factors. Factories often conduct tests for tensile strength, impact resistance, and dimensional accuracy.

4. Finishing Depending on the application, HDPE fittings may undergo additional finishing processes, such as surface treatment or coating to enhance durability or appearance.

5. Packaging and Distribution The final step is packaging the finished products for distribution. Factories may provide customization options for packaging, including branding and labeling to meet clients' specific requirements.

Advantages of HDPE Conduit Fittings

hdpe conduit fittings factory

HDPE conduit fittings offer a multitude of advantages compared to traditional materials like PVC or metal

- Durability HDPE is resistant to corrosion, rust, and degradation caused by chemical exposure

. This durability extends the lifespan of installations, reducing the need for frequent replacements.- Weight HDPE fittings are lighter than their metal counterparts, making them easier to handle and install. This results in lower transportation costs and reduced labor requirements.

- Flexibility The inherent flexibility of HDPE reduces the risk of damage caused by ground movements or impacts, offering a reliable solution in areas prone to seismic activity or heavy traffic.

- Environmental Impact HDPE is recyclable, allowing manufacturers to reduce waste and promote sustainability. Additionally, HDPE fittings do not leach harmful chemicals, making them safe for use in sensitive environments.

Innovations in HDPE Manufacturing

The HDPE conduit fittings factory sector is continuously evolving, driven by advancements in technology and an increasing emphasis on sustainability. Recent innovations include

- 3D Printing Utilizing 3D printing technology allows for rapid prototyping of fittings and customized designs tailored to specific client needs. This technology reduces lead times and opens new avenues for product development.

- Smart Fittings The integration of smart technology into HDPE fittings is on the rise. These smart fittings can monitor conditions such as pressure and temperature, providing real-time data for maintenance and allowing for proactive management of utilities.

- Eco-Friendly Production Many HDPE factories are adopting environmentally friendly practices by minimizing waste in the production process, utilizing renewable energy sources, and implementing closed-loop systems for recycling excess materials.

Conclusion

The HDPE conduit fittings factory plays a pivotal role in modern infrastructure, supporting essential services in telecommunications, electrical systems, and beyond. Through innovative manufacturing processes, a commitment to sustainability, and the production of durable, high-quality products, these factories are well-equipped to meet the demands of a rapidly evolving industry. As technology continues to advance, the future of HDPE conduit fittings remains bright, promising enhancements that will further solidify their position as a vital component in construction and utility applications.

-

HDPE Compression Fittings Durable & Reliable PP Compression Fittings Supplier

NewsJun.24,2025

-

High-Quality PVC Borehole Pipes - Durable Pipes from Leading PVC Manufacturer

NewsJun.10,2025

-

High-Quality PVC Borehole Pipes Types of Pipes by Leading PVC Manufacturer

NewsJun.10,2025

-

Durable Screen Pipes & HDPE-PVC Connectors Expert Solutions

NewsJun.10,2025

-

Premium HDPE Conduit Pipes Durable & Corrosion-Resistant

NewsJun.10,2025

-

Premium HDPE Elbows Durable Corrosion-Resistant Piping Solutions

NewsJun.09,2025