Apr . 24, 2024 15:29 Back to list

HDPE PIPE: THE COMPLETE GUIDE

HDPE PIPE: THE COMPLETE GUIDE

HDPE Pipe: What Is It & Why It's the Best Piping Choice in 2023?

What Is HDPE Pipe?

HDPE (High Density Polyethylene) pipe, simply put, is a type of plastic pipe commonly used to replace old or corroded pipelines, transfer low-temperature water, gas, chemical, and sewage. In recent years, it has also been used for telecommunication conduits.

It is lightweight yet strong, bends without breaking, and lasts for ages without rusting – making it a preferred choice for many municipal and industrial water applications for over 60 years.

Imagine this: You've got a piping project on your hands. You've got a choice to make, and it feels like a million-dollar question.

Which material should you pick? Copper? Steel? PVC?

While getting the right pipe for the job is key, one must not overlook its lifespan, cost-effectiveness, and reliability. After all, they are the heartbeat of your project's success and lifeline.

In fact, making one wrong move with materials not only could land you in a world of constant headaches – leaks, bursts, repairs, and escalating costs.

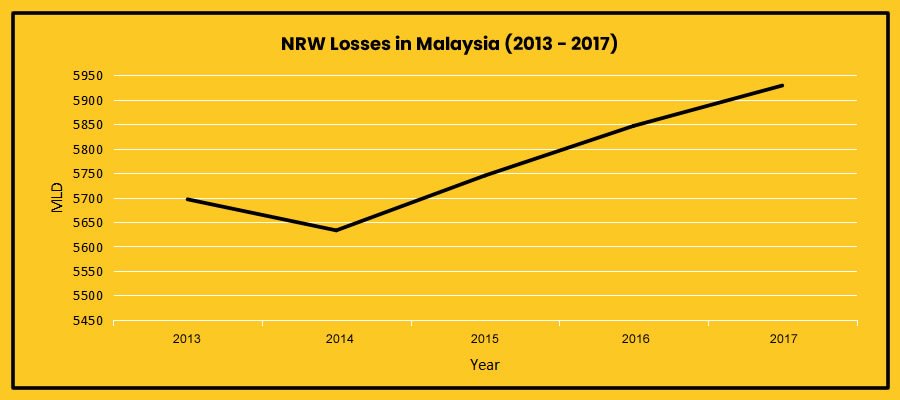

Research even shows that the use of aging and corrosion-prone pipes is among the main factors contributing to pipe breaks and high non-revenue water (NRW) rates in Malaysia.

This is especially true for homes and projects built before the mid-1990s.

Well, if all these sound familiar to you and you are looking for a solution to it, then HDPE pipe is your answer.

In this guide, we're going to take a deep dive into why HDPE pipe is the champion choice for your piping needs in 2023. Let's get started!

How HDPE Paved Its Way to the Top?

Way back years ago, our choices for piping materials were like the old tunes on the radio – copper, steel, cement, and PVC.

While they served their purposes, they had limitations such as corrosion or cracking at cold temperatures. That’s when HDPE stepped into the spotlight – offering a mix of strength, adaptability, and cost-saving magic.

Its reliability and successful performance history, have later, made HDPE the top choice – pushing older materials into the background.

Today, as many industries (especially the telecommunications and construction sectors) realized its benefits, the use of HDPE pipes is witnessing a steady growth at an annual rate of 4.5 percent.

But you might be wondering: what exactly makes these pipes so special? Stick around, as we're going to break down the features one by one next.

Advantages of HDPE Pipe

Now, close your eyes and imagine the ideal pipe.

What comes to mind? Flexible? Long-lasting? Cost-efficient?

The great news – HDPE ticks all those boxes and then some. Let's get into the details:

Flexibility

Like the gymnasts of the piping world, HDPE pipes can bend without breaking. This means they can fit various terrains and environments without easily cracking or getting damaged.

Their adaptability also reduces the need for joints and connectors – making installations easier and quicker.

Tough & Durable

HDPE pipes are built to last. Be it extreme cold or burning heat, these pipes don't crack under pressure. This long-lasting quality means fewer replacements and repairs in the long run.

In fact, they are even expected to last up to or more than 100 years.

No Rusting

Unlike metals, HDPE doesn't rust or corrode. It's like the superhero that doesn’t age – always looking good and ensuring your water or materials flow through cleanly.

Chemical Resistance

If your project involves transporting chemicals, HDPE is the choice.

It doesn’t degrade or react when exposed to most chemicals, making it ideal for handling corrosive acids and alkalis.

Lightweight

Despite their strength, HDPE pipes are light, making them easier to transport and install. This lightness not only saves time but cuts down your costs during installation.

Environmentally Friendly

Here’s a bonus for the eco-warriors out there: HDPE pipes have a lower carbon footprint compared to other materials. Plus, they’re recyclable, making them an even more sustainable choice.

Cost-Effective

While it might seem a bit pricier initially, HDPE pays off in the long run with fewer repairs or replacements, and a long lifespan.

Comparison with Other Materials: Which is Better?

We've talked about the many advantages of HDPE pipes, but how do they stack up against other materials like copper, steel, and PVC? After all, they have been the go-to choices for years and come with their own sets of benefits.

In this section, we'll put HDPE in a direct face-off with these materials, breaking down the pros and cons of each. Our aim? To give you a comprehensive view, so that you can make the best-informed decision for your project. Let’s start!

HDPE vs Copper Pipe

Well, copper is a classic choice and has been used for hundreds of years. It’s shiny, conducts heat well, and doesn’t rust – making it a top choice for hot water lines. Plus, it’s excellent for discouraging bacterial growth.

But, if you’re looking for easy installation and zero corrosion issues, HDPE takes the crown. Unlike copper, which could sometimes impart a metallic taste in water, HDPE is resistant to most aggressive chemicals – ensuring the purity of your water.

When we talk cost, HDPE is more affordable, especially given that copper prices can fluctuate.

HDPE vs Steel Pipe

Steel is strong, no doubt about it. But it can rust over time, especially when in contact with certain soil types or if its protective coating gets compromised. This means periodic checks and potential replacements.

HDPE doesn’t have this problem – making it perfect for underground applications or in places with high moisture. Its lightweight and ease of installation also mean that you'll spend less on maintenance and repairs.

In short, for a worry-free choice, go with HDPE.

HDPE vs PVC Pipe

We've previously talked about this face-off in detail in our blog – PVC vs. Poly (or HDPE) Pipe. Here’s a quick recap:

PVC is a common choice for many, especially when budget is a concern. However, when it comes to flexibility, longevity, and no chemical leaching, HDPE undoubtedly takes the upper hand.

Plus, HDPE offers added benefits like UV damage resistance that PVC struggles with.

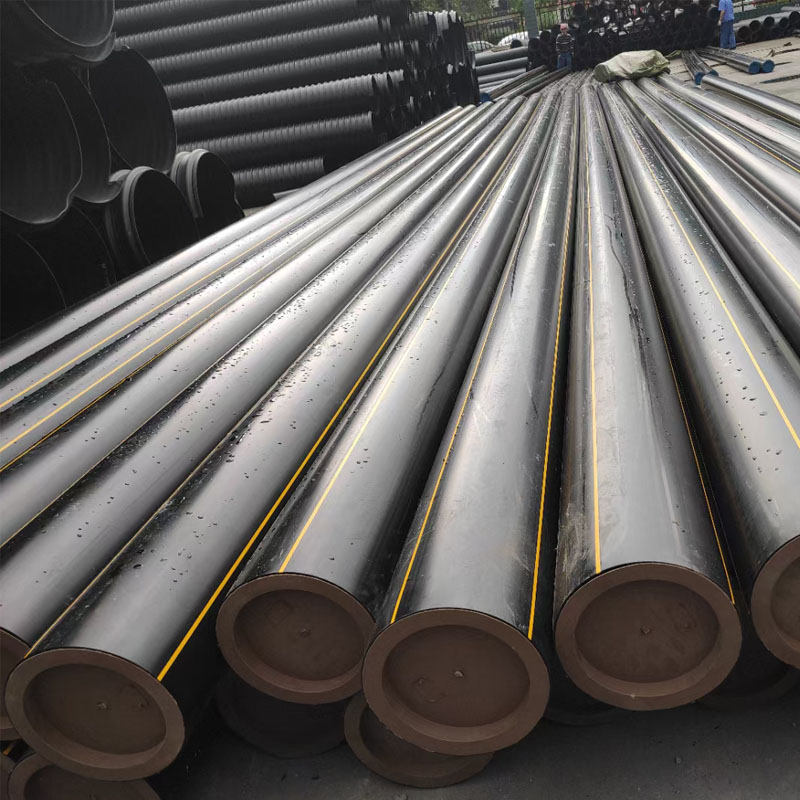

DN50 HDPE pipes in coils

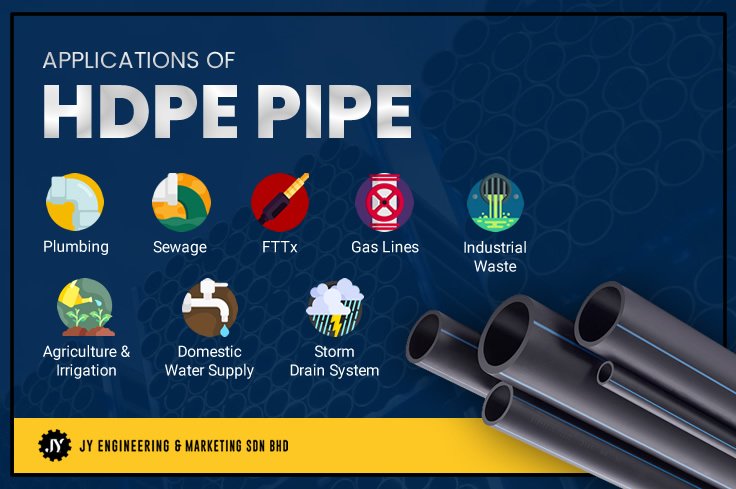

What Can HDPE Pipe Be Used For?

Now that you’ve seen the ins and outs of HDPE and its unbeatable features compared to other materials, it’s time for me to show you where these pipes are really making a ‘splash’.

From home to commercial spaces and big cities, HDPE fits in everywhere. Let’s check them out together!

Plumbing: Is HDPE Pipe Safe for Drinking Water?

Made of food-grade polyethylene, HDPE pipes are great for home plumbing, especially for the transfer of potable water. They don't rust, which means clean water.

They also have fewer leak issues, so no surprise water bills.

Sewage

With HDPE pipes handling sewage, you can be assured of a smooth flow and free from corrosion. They won’t easily crack or break, meaning they're great for preventing leaks or spills.

FTTx

Telecom companies prefer HDPE because it is lightweight, flexible, and durable – making it ideal as a protective conduit for fiber optic cables.

Additionally, it is cost-effective, doesn't take up much space, and is easier to install than other materials.

Gas Lines

When it's about transporting gas, there's no room for error.

HDPE pipes step up to the plate with their non-corrosive and durable nature, ensuring every ounce of gas flows safely without leaks.

In fact, 95% of all gas service lines in North America today are counting on HDPE pipe systems for their reliability.

Industrial Waste Transport

Dealing with industrial waste is easier and a whole lot safer with HDPE pipes.

Whether it's acidic or alkaline waste, hot or cold, their chemical resistance and leak-proof nature mean no reactions, no leaks, just secure transportation – preventing groundwater pollution.

Agriculture and Irrigation

HDPE makes irrigation smoother and effortless with its hassle-free installation.

These pipes are tough but lightweight, making them easy for farmers to move around large fields. Plus, they can withstand sunlight, so they last longer outdoors.

Their flexibility also allows them to be used on uneven terrains, making them suitable for agriculture where water needs to be channeled to different parts of the land.

Domestic Water Supply

Municipalities have a massive responsibility to ensure clean water reaches every household. And, HDPE fits the bill.

These pipes ensure the water remains pure with their rust-free and long-lasting nature. Plus, they don’t leak.

Storm Drain System

When there’s heavy rain, you need reliable drainage to keep those streets flood-free. That's where HDPE comes into play.

These pipes can handle lots of water, and their flexibility means they won’t easily break or crack.

Side Note: Specs, Classification & Grades

You are now familiar with the benefits and applications of HDPE. But, it's also crucial to understand its specifications and classifications.

After all, not every HDPE pipe is created equal, and the right choice can be pivotal for your project's long-term success.

HDPE pipes come in different types, based on how much pressure they can handle (PN 2.5, PN 4, PN 16, etc.) or the kind of material they are made from (PE 100, PE 80, and PE 32).

Today, we're focusing on two popular ones: PE80 and PE100.

PE 80

Think of PE 80 as the everyday HDPE pipe. It is perfect for regular water, gas, and industrial applications. Plus, it’s a top pick if you need two layers of pipes or if you are working with wastewater.

PE 100

Now, PE 100 is like PE 80's stronger sibling. It uses less material, has a bigger inside space for more flow, and holds up brilliantly, especially in really cold temperatures (down to -30°C).

Conclusion

By now, it's undeniable: HDPE pipes are not just a choice, they're the solution.

They have set the gold standard in the piping industry, combining flexibility, durability, cost-efficiency, and eco-friendliness like no other. From homes to industries, their applications are vast, proving that they are the real champions in the piping world.

I hope this guide provides you with a clear understanding of how these pipes would benefit you.

However, it's also crucial that you're using the right pipe from a trusted source. After all, not all HDPE is crafted equal.

-

Water Pressure Optimization for HDPE Pipe for Irrigation

NewsAug.07,2025

-

Temperature Tolerance of UPVC Column Pipes

NewsAug.07,2025

-

Root Intrusion Resistance of PVC Sewer Pipe

NewsAug.07,2025

-

Leak Prevention in PPR Plumbing Pipe Connections

NewsAug.07,2025

-

Installation Steps for HDPE Water Supply Pipe

NewsAug.07,2025

-

Cleaning Techniques for Water Lines Under Sink

NewsAug.07,2025