Jul . 26, 2024 19:16 Back to list

Factors Influencing the Cost of HDPE Pipes in China and Their Market Trends

Understanding the Cost of HDPE Pipes in China

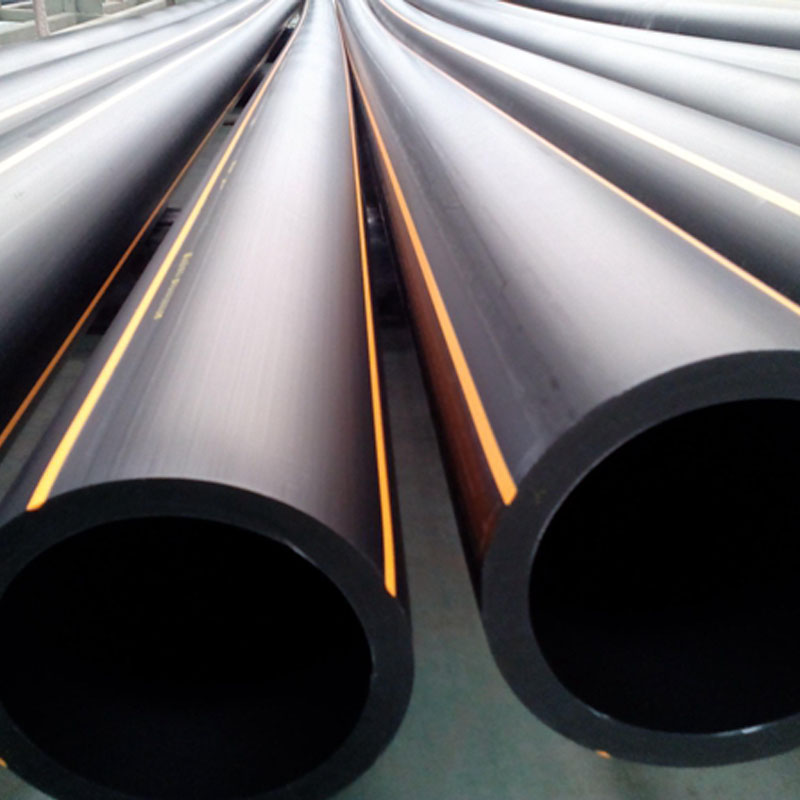

High-Density Polyethylene (HDPE) pipes have gained significant popularity in various sectors, including construction, agriculture, and water supply systems. With their high strength-to-weight ratio, flexibility, resistance to acids, and durability, HDPE pipes are increasingly preferred over traditional materials such as steel or PVC. In this article, we will explore the factors influencing the cost of HDPE pipes in China, providing insights into both the production and market aspects.

Production Costs

One of the primary factors affecting the cost of HDPE pipes is the production process itself. The manufacturing of HDPE pipes involves several steps, including the procurement of raw materials, extrusion, and quality control.

1. Raw Materials The cost of HDPE resin, the primary raw material for these pipes, fluctuates based on global oil prices, as HDPE is a petroleum-based product. In regions where crude oil prices are stable, producers may benefit from lower costs, thus making the HDPE pipes more affordable. Conversely, any spikes in oil prices can lead to increased production costs, which are often passed onto consumers.

2. Manufacturing Technology The technological advancements in the production process can also influence cost. Modern extrusion machines tend to be more efficient and faster, reducing operational costs. However, the initial investment in such state-of-the-art technology can be high. Manufacturers that can balance these costs effectively will have a competitive edge in the market.

3. Labor Costs Labor expenses in China can also impact the cost of HDPE pipes. While labor costs are generally lower in China compared to Western countries, regional disparities exist. Manufacturers located in coastal cities may incur higher labor expenses than those in more rural areas.

Market Dynamics

china hdpe pipe cost

Beyond production, several market dynamics play a role in determining the price of HDPE pipes in China

.1. Supply and Demand The basic economic principle of supply and demand significantly influences the cost. During periods of high demand for infrastructure development or agricultural projects, prices may surge. Conversely, during economic downturns or when demand slows, prices may decrease.

2. Competition The HDPE pipe market in China is competitive with a myriad of manufacturers, which can drive prices down. However, this competition also leads to variability in quality; cheaper pipes may not provide the same efficiency or longevity as those from more reputable manufacturers. It is crucial for buyers to consider quality alongside cost.

3. Regulatory Environment China’s regulatory framework around construction materials can impact the costs of HDPE pipes. Stricter environmental regulations may lead manufacturers to invest in cleaner and more eco-friendly production methods, potentially raising costs.

4. Export Factors For buyers outside China, fluctuations in currency exchange rates and shipping costs can influence the final price. As global trade dynamics change, so too can the competitiveness of Chinese HDPE pipes in international markets.

Conclusion

The cost of HDPE pipes in China is influenced by a myriad of factors, including production costs, market dynamics, and external economic conditions. For buyers, whether local or international, understanding these elements is essential to making informed purchasing decisions. Ultimately, while cost is a significant aspect, it is equally important to assess the quality and reliability of the HDPE pipes being purchased. Balancing cost with quality will ensure sustainable use and long-term savings in any application, from agricultural irrigation systems to urban infrastructure projects.

-

High-Quality PVC Borehole Pipes - Durable Pipes from Leading PVC Manufacturer

NewsJun.10,2025

-

High-Quality PVC Borehole Pipes Types of Pipes by Leading PVC Manufacturer

NewsJun.10,2025

-

Durable Screen Pipes & HDPE-PVC Connectors Expert Solutions

NewsJun.10,2025

-

Premium HDPE Conduit Pipes Durable & Corrosion-Resistant

NewsJun.10,2025

-

Premium HDPE Elbows Durable Corrosion-Resistant Piping Solutions

NewsJun.09,2025

-

Premium HDPE Electrofusion Fittings Leak-Free Solutions

NewsJun.09,2025