Aug . 12, 2024 04:14 Back to list

Comparison of PVC and PPR Pipes Exploring Their Features, Benefits, and Suitable Applications

PVC Pipe vs. PPR Pipe A Comprehensive Comparison

When it comes to plumbing and piping systems, choosing the right material is crucial for efficiency, durability, and cost-effectiveness. Two commonly used pipe types are PVC (Polyvinyl Chloride) and PPR (Polypropylene Random Copolymer). Both have unique attributes, advantages, and disadvantages that cater to different applications and environments. This article aims to provide a detailed comparison between PVC and PPR pipes to help you make an informed decision for your next project.

Material Composition and Properties

PVC pipes are made from a synthetic plastic polymer, which is known for its strength, lightweight nature, and resistance to corrosion. They are commonly used in drainage, irrigation, and various plumbing applications due to their versatility and cost-efficiency. PVC pipes are available in a range of sizes and diameters, making them suitable for both residential and industrial applications.

On the other hand, PPR pipes are made from a type of polypropylene that is known for its high durability and flexibility. PPR is resistant to high temperatures and does not corrode, making it ideal for hot water supply systems and heating applications. Additionally, PPR pipes have a smoother interior surface, which reduces friction and enhances flow efficiency.

Installation and Maintenance

One of the key advantages of PVC pipes is their ease of installation. They can be quickly cut and joined using solvent cement, which makes them a popular choice for DIY projects. PVC fittings are readily available, and the installation process requires minimal special tools, allowing for quick completion of plumbing jobs.

PPR pipes, however, require a fusion welding process for installation, which can be more time-consuming and necessitates specialized tools. Although this method provides strong, leak-proof joints, the initial installation cost may be higher due to the required equipment and technical expertise.

In terms of maintenance, both types of pipes are durable and require little upkeep. However, PVC pipes can become brittle over time, especially when exposed to UV light or extreme temperatures. In contrast, PPR pipes have a longer lifespan, generally lasting up to 50 years or more with minimal degradation.

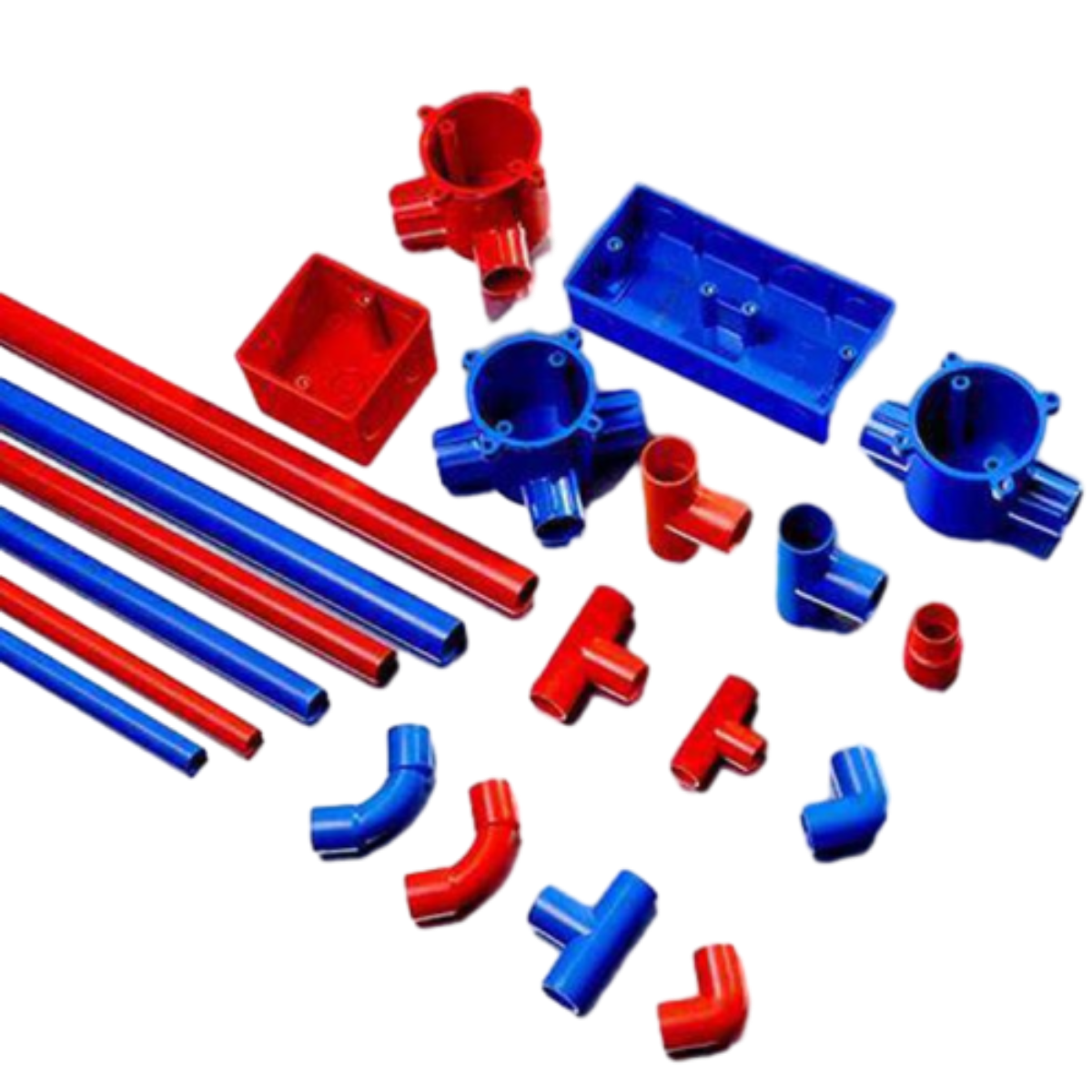

pvc pipe vs ppr pipe products

Cost Considerations

When comparing costs, PVC pipes are typically less expensive than PPR pipes, making them a more budget-friendly option for various applications. The lower material cost and ease of installation can significantly reduce overall project expenses, especially for large-scale projects such as plumbing systems in commercial buildings.

While PPR pipes may have higher initial costs, their longevity and performance can result in savings over time. They are more energy-efficient due to their heat retention capabilities, which can lower energy bills in hot water applications. Furthermore, the reduced need for repairs and replacements can justify the higher upfront investment.

Applications

PVC pipes are ideal for applications such as drainage, sewage, and irrigation. Their resistance to chemical exposure makes them suitable for transporting a wide range of fluids, including wastewater. They are not recommended for hot water applications due to their potential to soften under high temperatures.

Conversely, PPR pipes excel in hot and cold water supply systems, heating installations, and even in industrial environments where high durability is needed. Their flexibility and resistance to temperature variations make them a superior choice for modern plumbing solutions.

Conclusion

In summary, both PVC and PPR pipes offer unique benefits and can serve different needs effectively. PVC pipes are an excellent choice for low-cost and straightforward plumbing applications, especially in drainage and irrigation systems. Meanwhile, PPR pipes provide enhanced durability and flexibility, making them ideal for hot water and heating applications. Ultimately, the decision between PVC and PPR pipes should be based on specific project requirements, budget constraints, and long-term maintenance considerations. By carefully assessing the pros and cons of each option, you can ensure a reliable and efficient piping system for your needs.

-

HDPE Compression Fittings Durable & Reliable PP Compression Fittings Supplier

NewsJun.24,2025

-

High-Quality PVC Borehole Pipes - Durable Pipes from Leading PVC Manufacturer

NewsJun.10,2025

-

High-Quality PVC Borehole Pipes Types of Pipes by Leading PVC Manufacturer

NewsJun.10,2025

-

Durable Screen Pipes & HDPE-PVC Connectors Expert Solutions

NewsJun.10,2025

-

Premium HDPE Conduit Pipes Durable & Corrosion-Resistant

NewsJun.10,2025

-

Premium HDPE Elbows Durable Corrosion-Resistant Piping Solutions

NewsJun.09,2025