Nov . 22, 2024 16:21 Back to list

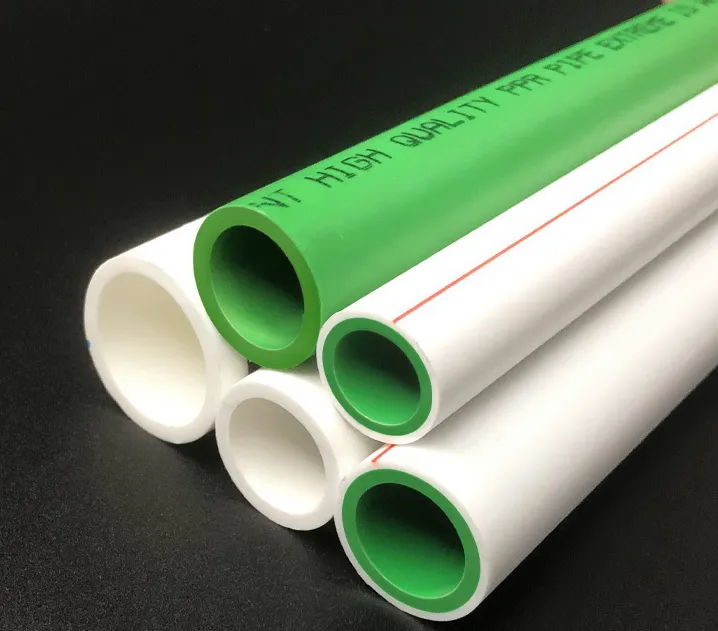

Choosing the Best PPR Water Pipe

PPR (Polypropylene Random Copolymer) water pipes have revolutionized plumbing and water distribution due to their high durability, excellent resistance to heat and pressure, and non-toxic material, making them ideal for both residential and commercial applications. In this guide, we’ll discuss the advantages of PPR water pipes, how to choose reliable PPR water pipe manufacturers, and what factors influence PPR water pipe prices.

Why PPR Water Pipes Are a Top Choice

PPR water pipes are manufactured from high-quality polypropylene material, known for its strength and long lifespan. Here’s why they are preferred in many applications:

- Durability and Long Lifespan: PPR pipes are resistant to corrosion and scale buildup, which often shortens the lifespan of traditional metal pipes. They last over 50 years when installed correctly.

- Heat and Pressure Resistance: PPR pipes can handle high pressures and temperatures up to 95°C (203°F), making them suitable for both hot and cold water applications.

- Non-Toxic and Safe for Drinking Water: PPR material is food-grade and does not leach harmful chemicals, making it ideal for drinking water supply.

- Thermal Insulation: PPR pipes have low thermal conductivity, which reduces heat loss in hot water systems, contributing to energy efficiency.

- Leak Resistance: These pipes have a smooth internal surface, reducing friction loss and lowering the risk of leaks.

Types of PPR Water Pipes

Different types of PPR pipes are available based on application, thickness, and pressure tolerance. Here’s a brief overview of the most common types:

Standard Cold Water PPR Pipes:

- Application: Used for cold water transport systems.

- Feature: They have basic pressure resistance and are usually more affordable.

Hot Water PPR Pipes:

- Application: Designed for transporting hot water in plumbing systems.

- Feature: Enhanced heat resistance, suitable for applications where water temperatures are consistently high.

UV-Resistant PPR Pipes:

- Application: Used in outdoor settings where pipes are exposed to sunlight.

- Feature: These pipes are treated to withstand UV radiation, which can degrade untreated PPR pipes over time.

Composite PPR Pipes:

- Application: Created with additional reinforcement materials like fiberglass for added strength.

- Feature: Ideal for high-pressure or industrial applications.

Antibacterial PPR Pipes:

- Application: Used in areas with strict hygiene standards, such as hospitals or food processing plants.

- Feature: Infused with antibacterial agents to prevent microbial growth within the pipes.

Choosing Reliable PPR Water Pipe Manufacturers

Selecting a dependable PPR water pipe manufacturer is essential to ensure high quality and long-lasting performance. Here are key factors to look for:

Quality Certifications:

- Look for manufacturers who have international certifications, such as ISO, NSF, or ASTM, which guarantee that their products meet high-quality standards for safety and durability.

Product Variety:

- Reputable manufacturers offer a wide range of PPR pipe types and sizes, allowing you to find the specific pipe that meets your project’s requirements.

Advanced Manufacturing Technology:

- Leading manufacturers use state-of-the-art technology and adhere to strict production standards. This results in pipes with uniform thickness, consistent material quality, and minimal defects.

Reliable Raw Material Sourcing:

- The quality of raw materials greatly influences the durability and performance of PPR pipes. Manufacturers that source high-quality PPR resins from trusted suppliers usually deliver superior products.

Customer Support and Warranty:

- A good manufacturer provides excellent customer support, technical advice, and warranty options, ensuring that customers get assistance before, during, and after purchase.

Market Reputation:

- Established manufacturers with positive customer reviews and a strong presence in the market often deliver more reliable products. Customer testimonials and references are great indicators of a company’s reliability.

Competitive Pricing:

- While the cheapest option isn’t always the best, competitive pricing from manufacturers can help you stay within budget without sacrificing quality.

Factors Influencing PPR Water Pipe Prices

Several factors impact the price of PPR water pipes. Understanding these can help you make informed decisions and budget effectively:

Pipe Type:

- Basic cold water pipes are generally more affordable than hot water pipes, which need to be more durable to withstand higher temperatures. UV-resistant and antibacterial pipes also tend to cost more due to additional materials or treatments.

Pipe Diameter and Thickness:

- Larger diameters and thicker pipes require more raw materials, increasing their cost. Choosing the right size and thickness according to the project requirements is essential to avoid overspending.

Quality of Raw Materials:

- High-quality PPR resins cost more but result in better pipes. Trusted manufacturers may charge a premium, but the pipes will generally last longer and perform better.

Brand and Manufacturer Reputation:

- Established brands may charge more due to their reputation and the quality assurance they offer. However, paying slightly more for a recognized brand can result in fewer maintenance issues over time.

Quantity and Bulk Orders:

- Manufacturers often provide discounts for bulk purchases. If you’re working on a large project, consider ordering all pipes from the same manufacturer to take advantage of bulk pricing.

Installation and Shipping Costs:

- Shipping fees may add to the final cost, especially for large-diameter or heavy pipes. Local manufacturers might offer lower shipping costs, which is worth considering if you’re on a budget.

Regional Market Conditions:

- In areas with high demand or limited suppliers, prices can be higher. Additionally, seasonal fluctuations and raw material prices can affect the market rate for PPR pipes.

Tips for Getting the Best PPR Water Pipe for Your Needs

- Assess Your Project Requirements: Decide whether you need hot or cold water pipes, outdoor UV-resistant options, or pipes for high-pressure applications. This will help you choose the correct type and avoid unnecessary costs.

- Check for Local Manufacturers: If feasible, buying from a nearby manufacturer can reduce shipping costs and provide easier access to customer support if needed.

- Look for Manufacturer Deals and Warranties: Some manufacturers offer warranties and after-sales support that add value to your purchase. This is particularly important for large projects, where long-term reliability is crucial.

- Request Bulk Quotes: If your project requires extensive piping, request a quote for a bulk order to take advantage of potential discounts.

When choosing PPR water pipes for your project, selecting a reliable PPR water pipe manufacturer is essential to ensure durability and quality. Consider the types of pipes available, the reputation and capabilities of different manufacturers, and the factors that influence PPR water pipe prices. By making an informed decision, you’ll not only get high-quality pipes but also optimize your budget, ensuring a long-lasting and efficient water distribution system.

-

Unveiling the Magic of PVC Irrigation Pipe

NewsJun.11,2025

-

Unlock Pipe Perfection with PPR Plumbing

NewsJun.11,2025

-

Unleashing the Hidden Potential of HDPE Tubing

NewsJun.11,2025

-

The New Frontier of PPR Plumbing Fittings Innovation

NewsJun.11,2025

-

Revolutionizing with PVC Tubing's Hidden Powers

NewsJun.11,2025

-

Advantages of HDPE Pipe in Potable Water Systems

NewsJun.11,2025