Apr . 29, 2024 12:30 Back to list

Brief Overview of PVC Pipes

Polyvinyl Chloride (PVC) pipes are a type of synthetic plastic polymer that have gained widespread use in numerous industries and applications. These pipes are known for their exceptional versatility, strength, and resistance to corrosion. PVC pipes are manufactured in various types, each tailored to specific needs, making them a vital component in modern infrastructure. Their seamless blend of durability and affordability has cemented their role as a primary choice in plumbing, construction, irrigation, and more.

PVC pipes have revolutionized industries ranging from plumbing to agriculture, from electrical systems to manufacturing. Their importance lies in their ability to meet the demands of diverse applications. These pipes are known for their resistance to corrosion, making them a reliable choice for water supply and drainage systems. They also offer cost-effective solutions, reducing the financial burden of various projects. Their wide availability and ease of installation have further contributed to their ubiquity in residential, commercial, and industrial settings. As a result, PVC pipes play a pivotal role in maintaining the modern world’s infrastructure and ensuring the efficient functioning of essential systems.

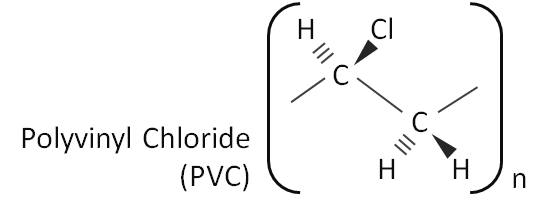

Definition and Composition of PVC

Polyvinyl Chloride, commonly known as PVC, is a synthetic plastic polymer made from a combination of vinyl chloride monomers. During its production, these monomers undergo polymerization, forming long chains of PVC molecules. This process results in a versatile and durable material that can be shaped and molded into a variety of forms, including pipes.

The composition of PVC typically consists of the following elements:

- Vinyl Chloride Monomers: These are the building blocks of PVC. Through the polymerization process, these monomers combine to form the long chains characteristic of PVC.

- Additives: Various additives are incorporated into PVC formulations to enhance its properties. These may include stabilizers to prevent degradation, plasticizers to modify flexibility, and pigments for coloration.

Key Properties and Advantages

PVC pipes possess several key properties and advantages that have contributed to their widespread use:

- Durability: PVC pipes are known for their exceptional durability. They can withstand a wide range of environmental factors, including moisture, chemicals, and temperature fluctuations, without corroding or degrading over time. This longevity ensures a reliable and long-lasting solution for various applications.

- Affordability: PVC pipes are cost-effective compared to many alternative materials, making them an attractive choice for budget-conscious projects. Their affordability, combined with their durability, provides excellent value for money.

- Corrosion Resistance: One of the standout features of PVC pipes is their resistance to corrosion. Whether used for water supply, drainage, or chemical transport, PVC pipes remain unaffected by most corrosive substances, ensuring the purity and integrity of the transported materials.

- Lightweight: PVC pipes are lightweight, which simplifies handling and installation. This characteristic is especially advantageous in construction and plumbing, where ease of use and reduced labor costs are significant factors.

- Versatility: PVC pipes come in various types, each designed for specific applications. This versatility allows them to cater to a wide range of needs, from residential plumbing to industrial processes.

- Low Maintenance: Once installed, PVC pipes require minimal maintenance. They do not rust or corrode, reducing the need for repairs or replacements, which further contributes to cost savings.

- Eco-Friendly: PVC pipes are considered eco-friendly as they are recyclable. When their lifespan ends, they can be repurposed, reducing their environmental impact.

The unique combination of these properties and advantages has made PVC pipes a preferred choice for plumbing, construction, and a host of other applications, ensuring that they continue to play a pivotal role in shaping our modern infrastructure.

Types of PVC Pipes

PVC pipes come in several different types, each tailored to specific needs and applications. Understanding these variations is crucial when selecting the right type of PVC pipe for a project. Here are the main types:

1. Schedule 40 PVC Pipes:

Characteristics: Schedule 40 PVC pipes are lightweight and versatile. They have a standard wall thickness and are available in various lengths and diameters.

Common Applications: This type is widely used for various applications, including residential water supply lines, drainage systems, and irrigation.

A. Characteristics:

- Versatility: Schedule 40 PVC pipes are highly versatile and suitable for a wide range of applications. They are available in various lengths and diameters, making them adaptable to different project requirements.

- Standard Wall Thickness: These pipes have a standard wall thickness, which strikes a balance between strength and ease of installation. The thickness provides structural integrity while remaining lightweight.

- Affordability: Schedule 40 PVC pipes are budget-friendly, making them an attractive choice for cost-conscious projects. Their affordability does not compromise their quality and performance.

- Resistance to Corrosion: PVC pipes are inherently resistant to corrosion, ensuring long-term durability even in adverse environmental conditions.

B. Common Applications:

- Residential Water Supply: Schedule 40 PVC pipes are commonly used for residential water supply lines. Their resistance to corrosion and ease of installation make them a reliable choice for delivering clean, potable water to homes.

- Drainage Systems: These pipes are also employed in drainage systems to transport wastewater away from residential and commercial buildings. Their smooth interior prevents blockages and allows efficient drainage.

- Irrigation: In agriculture and landscaping, Schedule 40 PVC pipes are used for irrigation purposes. They can efficiently transport water to crops, gardens, and landscapes, ensuring proper hydration.

- Swimming Pool Plumbing: PVC pipes are the preferred choice for swimming pool plumbing due to their resistance to corrosion from chlorine exposure. They ensure the smooth flow of water for filtration and circulation systems.

- DIY Projects: Schedule 40 PVC pipes are often a go-to choice for DIY enthusiasts. Their versatility and ease of handling make them ideal for various small projects and custom installations.

2. Schedule 80 PVC Pipes:

Characteristics: Schedule 80 PVC pipes are thicker and more robust compared to Schedule 40. They are engineered to handle higher pressure and temperature conditions.

Common Applications: These pipes find use in industrial settings, industrial plumbing, chemical processing, and underground installations where more durability is required.

A. Characteristics:

- Enhanced Thickness: Schedule 80 PVC pipes are thicker and heavier than Schedule 40 pipes. This increased thickness provides greater strength and durability, making them suitable for applications where higher pressure and temperature conditions are encountered.

- Robust Construction: These pipes are engineered to withstand the rigors of industrial environments and are capable of handling more demanding conditions without deformation or failure.

- Chemical Resistance: Schedule 80 PVC pipes maintain their integrity when exposed to a wide range of chemicals and corrosive substances, making them ideal for chemical processing and industrial applications.

- Impact Resistance: Their thicker walls offer improved resistance to physical impact, ensuring they can withstand rough handling and external forces.

B. Common Applications:

- Industrial Plumbing: Schedule 80 PVC pipes are commonly used in industrial plumbing where they are tasked with transporting various fluids under high pressure. Their robust construction and resistance to corrosion make them well-suited for this purpose.

- Chemical Processing: Due to their exceptional chemical resistance, Schedule 80 PVC pipes are a preferred choice in chemical processing plants, where they handle the transport of aggressive chemicals without deteriorating.

- Underground Installations: The added thickness and durability of these pipes make them suitable for underground installations, such as buried water and sewer lines, where they can withstand the pressure from the surrounding soil.

- High-Temperature Environments: Schedule 80 PVC pipes can endure higher temperatures, making them appropriate for applications like industrial hot water lines and process piping where standard PVC might not suffice.

- Heavy-Duty Plumbing: In environments that require heavy-duty plumbing solutions, such as wastewater treatment facilities, Schedule 80 PVC pipes are used to ensure reliable and long-lasting performance.

The increased wall thickness and strength of Schedule 80 PVC pipes, combined with their resistance to corrosion and chemicals, make them the go-to choice for applications where the demands are greater. These pipes are essential components in industrial and commercial settings, ensuring the efficient and reliable transport of fluids under challenging conditions.

3. CPVC Pipes (Chlorinated Polyvinyl Chloride):

Characteristics: CPVC pipes are designed to withstand higher temperatures than standard PVC pipes. They are known for their excellent resistance to heat and chemicals.

Common Applications: CPVC pipes are often used in hot water systems, such as water heaters, and for hot water supply lines in residential and commercial buildings.

A. Characteristics:

- High Temperature Resistance: One of the primary characteristics of CPVC pipes is their exceptional ability to withstand high temperatures. They can handle hot water and liquids up to 200°F (93°C) without deforming or degrading, making them suitable for hot water systems.

- Chemical Resistance: CPVC pipes exhibit robust resistance to a wide range of chemicals, acids, and bases. This makes them ideal for applications where the transported fluids may be corrosive or reactive.

- Durability: CPVC pipes are highly durable and have a longer lifespan, thanks to their ability to withstand extreme temperature variations and resist corrosion.

- Smooth Interior: These pipes have a smooth inner surface, which not only ensures efficient fluid flow but also prevents scaling and the buildup of deposits, contributing to long-term performance.

B. Common Applications:

- Hot Water Systems: CPVC pipes are extensively used in hot water supply systems for residential, commercial, and industrial applications. Their ability to handle high temperatures makes them an excellent choice for water heaters, hot water distribution, and other hot water applications.

- Chemical Transport: In chemical processing plants, CPVC pipes are employed to transport a variety of chemicals safely. Their resistance to chemical corrosion ensures that transported substances remain uncontaminated.

- Fire Sprinkler Systems: CPVC pipes are a preferred material for fire sprinkler systems due to their heat resistance. They are capable of withstanding the high temperatures generated during a fire, ensuring the effectiveness of the sprinkler system.

- Commercial Plumbing: In commercial buildings and facilities where hot water is a necessity, CPVC pipes are used for both hot and cold water distribution, ensuring the reliable flow of water under varying temperature conditions.

- Residential Plumbing: CPVC pipes are also utilized in residential plumbing systems, particularly in regions with stringent building codes that require materials capable of handling high-temperature water.

CPVC pipes are prized for their ability to handle hot water and corrosive chemicals while maintaining their structural integrity. Their versatility and durability have made them a valuable asset in applications where standard PVC or other materials might not suffice

4. PVC Drain Waste Vent (DWV) Pipes:

Characteristics: DWV pipes are designed with a specific purpose—to efficiently remove waste from plumbing systems. They have a unique design to prevent blockages and maintain proper sanitation.

Common Applications: These pipes are crucial for drainage, waste, and venting purposes in plumbing systems.

A. Characteristics:

- Specific Design: DWV pipes are purpose-built for drainage, waste, and venting applications in plumbing systems. They feature a unique design tailored to efficiently remove waste and prevent blockages.

- Lightweight: Like other PVC pipes, DWV pipes are lightweight, making them easy to handle and install. Their low weight simplifies transportation and on-site handling.

- Smooth Interiors: These pipes have smooth, polished interiors that allow waste and water to flow freely. The smooth surface minimizes the likelihood of clogs and ensures efficient waste removal.

- Corrosion Resistance: DWV pipes, like all PVC pipes, are resistant to corrosion. This resistance ensures that they remain unaffected by the moisture and waste they come into contact with, maintaining their integrity over time.

B. Common Applications:

- Sanitary Drainage: DWV pipes are primarily used for sanitary drainage systems in residential, commercial, and industrial buildings. They efficiently transport wastewater and sewage away from fixtures, ensuring proper sanitation.

- Waste Removal: These pipes handle the removal of waste and debris from sinks, toilets, showers, and other plumbing fixtures. Their smooth interiors prevent waste build-up and blockages.

- Ventilation: DWV pipes also provide a crucial role in plumbing systems by venting sewer gases and allowing fresh air to enter the system. This prevents the build-up of noxious fumes and ensures proper functioning.

- Septic Systems: In septic systems, DWV pipes help transport effluent from the septic tank to the drain field. Their corrosion resistance is particularly important in this application due to the potentially corrosive nature of septic waste.

- Stormwater Drainage: DWV pipes may be used for stormwater drainage, especially in residential applications. Their smooth interiors help prevent debris and leaves from causing blockages in the drainage system.

DWV pipes are a vital component of plumbing systems, responsible for the efficient removal of waste and the prevention of blockages. Their specific design and corrosion resistance make them essential in maintaining proper sanitation and the functioning of plumbing systems in various settings.

5. PVC Pressure Pipes:

Characteristics: PVC pressure pipes are engineered to handle high-pressure applications, such as water mains and industrial processes. They come in various sizes and are known for their exceptional strength and durability.

Common Applications: You’ll find PVC pressure pipes in settings where high-pressure water distribution or conveying industrial fluids is necessary.

Each type of PVC pipe is engineered to excel in specific conditions and applications. Whether you require a lightweight and versatile option like Schedule 40 or a more robust solution for industrial use like Schedule 80, PVC pipes offer a diverse range of choices to suit your specific needs. Understanding the distinctions between these types is essential for selecting the right PVC pipe for your project.

A. Characteristics:

- High Pressure Tolerance: PVC pressure pipes are engineered to withstand high pressure, making them suitable for applications where water or other fluids are transported under significant force. They maintain their structural integrity even under substantial pressure.

- Durability: These pipes are highly durable and can endure a range of environmental conditions. They are resistant to corrosion, ensuring a long lifespan even in challenging settings.

- Varied Sizes: PVC pressure pipes come in various sizes to accommodate different project requirements. This flexibility in sizing allows for customization based on the specific application.

- Ease of Installation: Despite their robust construction, PVC pressure pipes are relatively easy to install. Their lightweight nature simplifies transportation and on-site handling.

B. Common Applications:

- Water Mains: PVC pressure pipes are frequently used for water mains and distribution networks. Their high-pressure tolerance ensures efficient and reliable water supply to residential, commercial, and industrial areas.

- Industrial Processes: These pipes play a crucial role in various industrial processes, such as conveying chemicals, fluids, and wastewater. Their ability to withstand high pressure and resistance to corrosion makes them ideal for this purpose.

- Agricultural Irrigation: PVC pressure pipes are used in agricultural irrigation systems where pressurized water is essential for efficient crop hydration. Their durability ensures consistent water supply to fields.

- Fire Protection Systems: In fire protection systems, these pipes are used to transport pressurized water to fire sprinklers, ensuring a rapid response to fire emergencies.

- Manufacturing and Processing: PVC pressure pipes find application in manufacturing and processing facilities, where they handle the transport of various fluids, including those involved in chemical production.

PVC pressure pipes are integral in ensuring the efficient and reliable transport of pressurized fluids in various settings. Their high-pressure tolerance, durability, and ease of installation make them a top choice for water distribution, industrial processes, and other applications where fluid flow under pressure is essential.

Common Applications of PVC Pipes

PVC pipes, in their various types, are widely used in a range of applications due to their versatility, durability, and cost-effectiveness. Some of the most common applications include:

- Water Supply: PVC pipes are extensively used for water supply systems, both in residential and commercial settings. Their corrosion resistance ensures the delivery of clean and safe drinking water.

- Drainage Systems: PVC pipes are crucial in drainage systems, effectively carrying wastewater and sewage away from buildings, preventing flooding, and maintaining sanitation.

- Irrigation: Agriculture and landscaping benefit from PVC pipes for irrigation purposes, as they efficiently transport water to crops and gardens.

- Plumbing: PVC pipes are the go-to choice for plumbing systems, serving hot and cold water supply lines and drain pipes in residential, commercial, and industrial buildings.

- Swimming Pool Plumbing: PVC pipes are ideal for swimming pool plumbing, as they can withstand the corrosive effects of pool chemicals and ensure proper water circulation and filtration.

- Electrical Conduits: In some cases, PVC pipes serve as electrical conduits, protecting electrical wiring and cables due to their non-conductive properties.

- Industrial Fluid Transport: PVC pipes are used in various industrial processes for transporting chemicals, wastewater, and other fluids, thanks to their corrosion resistance and durability.

- Fire Sprinkler Systems: They play a crucial role in fire protection systems by transporting pressurized water to fire sprinklers to quickly respond to fire emergencies.

- Septic Systems: PVC pipes are vital in septic systems, facilitating the transport of effluent from the septic tank to the drain field.

- Stormwater Drainage: In residential applications, PVC pipes are used for stormwater drainage, preventing waterlogged areas and ensuring efficient drainage.

- Chemical Processing: Due to their chemical resistance, PVC pipes are indispensable in chemical processing plants for transporting a wide range of chemicals safely.

- Industrial Plumbing: PVC pipes are used in various industrial plumbing applications, providing reliable fluid transport under demanding conditions.

- Fire Protection Systems: In addition to fire sprinkler systems, PVC pipes are employed in fire protection systems to ensure rapid water supply in the event of a fire.

The adaptability of PVC pipes to a broad spectrum of applications has solidified their status as a foundational component in modern infrastructure, construction, and industry. Their properties of strength, corrosion resistance, and affordability continue to make them a top choice in various sectors, ensuring efficient and reliable fluid transport and drainage.

Benefits of PVC Pipes

PVC (Polyvinyl Chloride) pipes are a popular choice in a wide range of applications, thanks to their numerous benefits.

Here are the key advantages of PVC pipes:

- Durability: PVC pipes are known for their exceptional durability. They can withstand a variety of environmental conditions, including moisture, chemicals, and temperature fluctuations, without corroding or deteriorating. This longevity ensures reliable and long-lasting performance.

- Affordability: PVC pipes are cost-effective compared to many other piping materials. Their affordability, combined with their durability, translates to excellent value for money. This makes them a budget-friendly choice for a wide range of projects.

- Low Maintenance: Once installed, PVC pipes require minimal maintenance. They do not rust, corrode, or degrade, reducing the need for repairs and replacements. This low-maintenance characteristic contributes to cost savings over time.

- Corrosion Resistance: PVC pipes are inherently resistant to corrosion. This resistance is essential, particularly in applications where the transported fluids may be corrosive. It ensures the pipes’ integrity and the purity of the materials being transported.

- Lightweight: PVC pipes are lightweight, which simplifies transportation, handling, and installation. Their low weight reduces labor costs and makes them an excellent choice for projects where ease of use is essential.

- Versatility: PVC pipes come in various types, each designed for specific applications. This versatility allows them to cater to a wide range of needs, from residential plumbing to industrial installations. It ensures that there’s a PVC pipe suitable for nearly every project.

- Environmental Friendliness: PVC pipes are considered eco-friendly because they are recyclable. When their lifespan ends, they can be repurposed, reducing their environmental impact and promoting sustainability.

- Resistance to Scaling and Deposits: The smooth interior of PVC pipes prevents the build-up of scale and deposits. This ensures efficient fluid flow and reduces maintenance requirements.

- Resistance to Biological Growth: PVC pipes are resistant to biological growth, preventing the development of mold, algae, and other microorganisms that can affect water quality.

- Non-Conductive: PVC is a non-conductive material, making it safe for use as electrical conduits. It provides insulation for electrical wires, reducing the risk of electrical hazards.

- Cost-Efficient Installation: The lightweight nature of PVC pipes simplifies installation and reduces labor costs. Their ease of handling allows for quicker project completion.

- Wide Availability: PVC pipes are readily available in the market, ensuring a consistent supply for construction and infrastructure projects.

The combination of these benefits makes PVC pipes an attractive choice for a wide range of applications, from plumbing to irrigation, and from chemical transport to electrical conduits. Their affordability, durability, and resistance to corrosion have solidified their position as a reliable and cost-effective piping solution.

FAQ

Are PVC Pipes Safe for Drinking Water?

Yes, PVC pipes are considered safe for transporting drinking water. They are non-toxic and do not leach harmful chemicals or contaminants into the water. In fact, PVC is commonly used in water supply systems in both residential and commercial settings, ensuring the delivery of clean and safe drinking water.

Can PVC Pipes Be Used for Underground Installations?

Yes, PVC pipes can be used for underground installations. In fact, they are often a preferred choice for underground applications such as buried water supply lines, sewage systems, and stormwater drainage. PVC’s resistance to corrosion and durability makes it suitable for withstanding the environmental conditions typically found underground.

What Is the Difference Between Schedule 40 and Schedule 80 PVC Pipes?

The primary difference between Schedule 40 and Schedule 80 PVC pipes is the thickness of the pipe walls. Schedule 80 PVC pipes have thicker walls compared to Schedule 40 pipes, making them more robust and able to handle higher pressure and temperature conditions. Schedule 40 pipes, on the other hand, have standard wall thickness and are lighter and more economical. The choice between the two depends on the specific needs of the project, with Schedule 80 being suitable for more demanding applications.

Are PVC Pipes Eco-Friendly?

Yes, PVC pipes are considered eco-friendly. They are recyclable and can be repurposed when they reach the end of their lifespan. This recyclability reduces their environmental impact and promotes sustainability. Additionally, the manufacturing process of PVC pipes consumes less energy compared to some other materials, further contributing to their eco-friendly status.

Can PVC Pipes Be Painted for Aesthetics?

PVC pipes can be painted for aesthetic purposes. However, it’s important to choose a paint that is compatible with PVC and can adhere well to its surface. PVC’s smooth surface may require priming to ensure proper paint adhesion. Keep in mind that painting PVC pipes is typically done for decorative or color-coding purposes and not for added protection, as PVC is naturally resistant to corrosion and does not require additional coatings for protection.

-

Water Pressure Optimization for HDPE Pipe for Irrigation

NewsAug.07,2025

-

Temperature Tolerance of UPVC Column Pipes

NewsAug.07,2025

-

Root Intrusion Resistance of PVC Sewer Pipe

NewsAug.07,2025

-

Leak Prevention in PPR Plumbing Pipe Connections

NewsAug.07,2025

-

Installation Steps for HDPE Water Supply Pipe

NewsAug.07,2025

-

Cleaning Techniques for Water Lines Under Sink

NewsAug.07,2025